In the realm of industrial manufacturing, ensuring the quality and reliability of components is paramount. Components integral to many mechanical systems must be rigorously validated for defects such as missing handles, bolts, or screws. The challenge lies in detecting these defects efficiently and accurately. This article delves into how advanced machine learning techniques can be leveraged to implement a robust detection and alert system for identifying defective components.

About Scanflow

Scanflow for MotorGear Defect Detection is an AI-powered solution tailored for identifying defects in gearmotors within industrial settings. It employs advanced machine learning algorithms and intelligent image processing to streamline the detection process, ensuring high accuracy and efficiency.

Scanflow seamlessly integrates with existing workflows and software infrastructure, supporting a wide range of platforms and development frameworks for easy deployment. Additionally, its offline functionality enables uninterrupted operation, even in areas with limited connectivity, ensuring continuous data capture and enhancing operational efficiency.

By accurately detecting defects in gearmotors, Scanflow helps manufacturers maintain high standards of quality control, reducing manual inspection efforts and minimizing production delays. Furthermore, its data security features, including encryption and offline storage, mitigate safety concerns and prevent unauthorized access, ensuring the integrity and confidentiality of sensitive information related to gearmotor inspection processes.

Objective

Our goal is to create an automated system that detects and alerts relevant personnel during the validation process of components exhibiting specific defects. This system aims to enhance accuracy, reduce manual inspection efforts, and ensure only quality-assured components proceed to the next stage of production.

Strategic Approach

- Data Collection: The foundation of any machine learning project is data. In collaboration with the client, we will gather a comprehensive dataset comprising high-resolution images of components, both defective and non-defective. This dataset will serve as the cornerstone for training and validating our model. The quality and diversity of this dataset are crucial, as they directly impact the model’s ability to generalize and perform well in real-world scenarios.

- Image Annotation: To enable our model to recognize defects, we must first annotate the images. Annotation involves labeling regions within the images that correspond to defects like missing handles, bolts, or screws. This process ensures that the model can identify these defects accurately. We will use specialized annotation tools and techniques to mark the defective regions precisely. This step is labor-intensive but essential for training a high-performing model.

- Dataset Preparation: Post-annotation, the next step is organizing the dataset. Efficient organization is crucial for training the model effectively and evaluating its performance accurately. The dataset will be split into training, validation, and test sets. The training set will be used to teach the model, the validation set will be used to tune the model parameters, and the test set will evaluate the model’s performance in unseen data. We will ensure that each set contains a balanced mix of defective and non-defective component images to prevent any bias.

- Model Training: For detecting component defects, we have created our own custom-built model. This model has been tailored specifically for our needs and is designed to accurately identify defects in components. By leveraging transfer learning, we can fine-tune a pre-trained model on our custom dataset, ensuring optimal performance. Transfer learning allows us to benefit from the knowledge gained by a model trained on a large, generic dataset, adapting it to our specific task with relatively little data.

Training Result

Training Hardware

The model training was conducted using high-performance hardware to expedite the process. This hardware configuration enabled us to train the model efficiently and effectively. The specifications of the hardware used are as follows:

Processor – Intel i7 14700KF with 28 CPUs @ 3.4 GHz

Memory – 32GB RAM

Graphics Card – NVIDIA RTX 4090

The training process took approximately 38 hours to complete in the specified hardware configuration. Utilizing such robust hardware ensures that the model training is both time-efficient and capable of handling the complexity of the task.

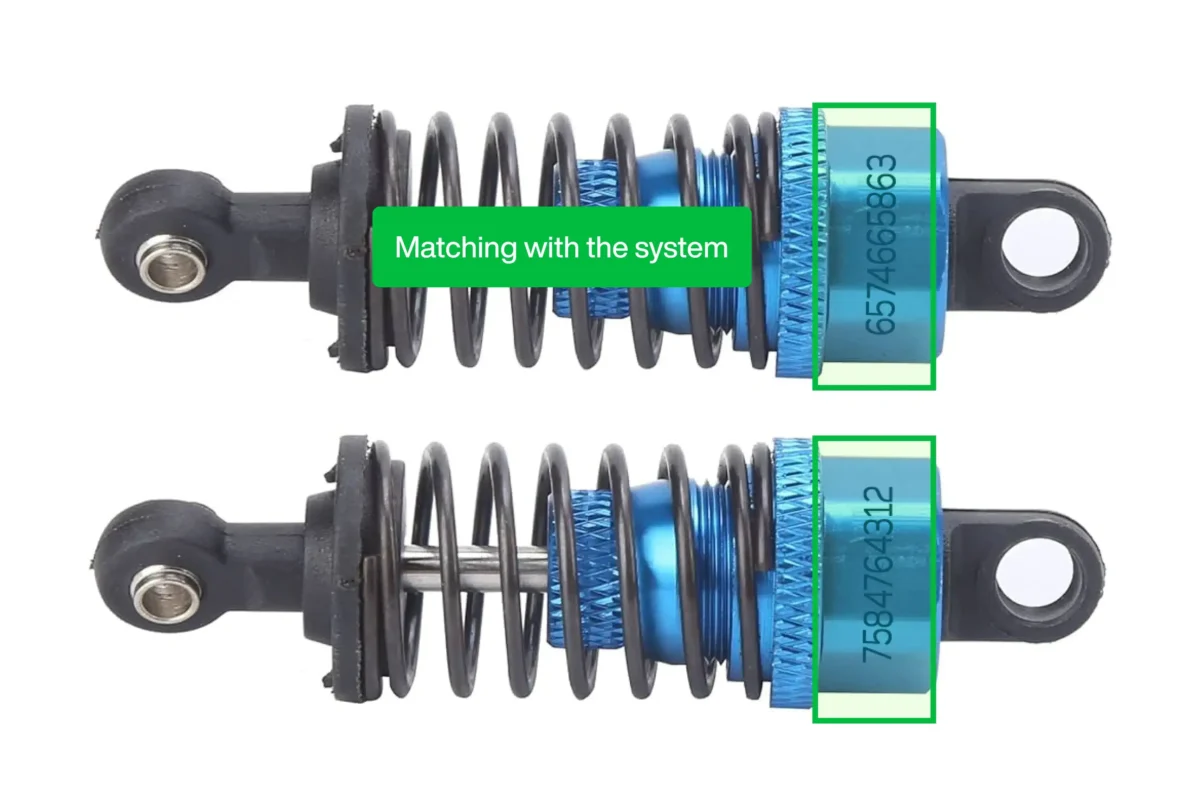

Real-Time Use Case

To demonstrate the model’s capabilities, we present images of a Helical Bevel Gear Motor. One image represents a defective motor, and the other represents a non-defective motor. The model’s ability to distinguish between these two scenarios is critical for practical deployment.

In the defective gear motor image, the model identifies missing handles, bolts, or screws by highlighting these areas with bounding boxes. In contrast, the non-defective gear motor image shows no highlighted regions, indicating that the component is free of defects.

Deployment and Real-Time Alerts

With the model trained and validated, the final step is deployment. Integrating the model into the component validation workflow involves several steps:

- System Integration: The model is integrated with the existing manufacturing software infrastructure. This allows for seamless interaction between the detection system and the production line.

- Continuous Monitoring: The system continuously monitors components as they pass through the validation stage. High-resolution cameras capture images, which are then processed by the model in real-time.

- Real-Time Detection: The model analyzes each image, identifying any defects instantly. The system can handle a high throughput of images, ensuring that the validation process does not become a bottleneck in production.

- Automatic Alert Generation: When a defect is detected, the system generates an automatic alert. This alert is sent to the relevant personnel, such as quality control inspectors or production managers, enabling immediate action to be taken.

This integration not only streamlines the validation process but also significantly reduces the risk of defective gear motors reaching the market. The real-time alert mechanism ensures that defects are addressed promptly, maintaining the overall quality of the components.

Conclusion

By adopting this advanced detection system, manufacturers can achieve a new level of precision in component quality control. Combining machine learning and real-time alert mechanisms ensures that only high-quality products proceed through the production line. This approach not only enhances operational efficiency but also maintains the integrity and reliability of components.

By implementing these cutting-edge techniques, manufacturers can ensure rigorous quality control and uphold the highest standards in component production. Integrating machine learning in defect detection represents a significant step forward in industrial manufacturing, promising to improve product quality and reduce operational costs.

In summary, our advanced detection system provides a comprehensive solution to the challenge of identifying defective components in gear motors. By leveraging the power of machine learning and high-performance hardware, we can deliver a robust and efficient system that meets the demands of modern manufacturing.