In today’s fast-paced world, businesses are turning to AI for data capture to collect, process, and manage complex information with greater accuracy and speed. This technology extends beyond simple data extraction, it efficiently handles alphanumeric data like VIN plate scanning, tire sidewall numbers, serial numbers, Bar codes, QR codes etc., ensuring precision even in the most challenging conditions.

Industries such as automotive, logistics, manufacturing, and retail are integrating AI visual inspection solutions and AI for data capture to streamline workflows, reduce manual errors, and enhance operational efficiency. This shift isn’t just a technological upgrade but it’s redefining how businesses capture and use data in real time.

- Expanding Data Capture Beyond Traditional Methods

AI is revolutionizing data capture by automating the collection of complex information across various environments. What once required manual data entry or specialized equipment can now be handled seamlessly by AI visual inspection workflows.

Key applications of AI in advanced data capture include:

VIN Plate Scanning: Essential in the automotive and logistics industries, AI quickly and accurately captures vehicle identification numbers, streamlining tracking, registration, and inventory.

Tire Sidewall Numbers: AI can extract detailed information from tire sidewalls, supporting product verification, recall management, and quality assurance in manufacturing.

Serial Number Scanning: Useful in electronics and industrial sectors, AI captures serial numbers for inventory tracking, warranty management, and equipment identification.

Alphanumeric Text Recognition: AI retrieves data from labels, machinery plates, and industrial documentation, ensuring error-free data input and reducing manual workload.

Why it matters?

AI captures data from worn, distorted, or low-visibility surfaces, ensuring accurate collection under challenging conditions. This reduces errors, enhances data consistency, and allows businesses to maintain accurate records without manual oversight.

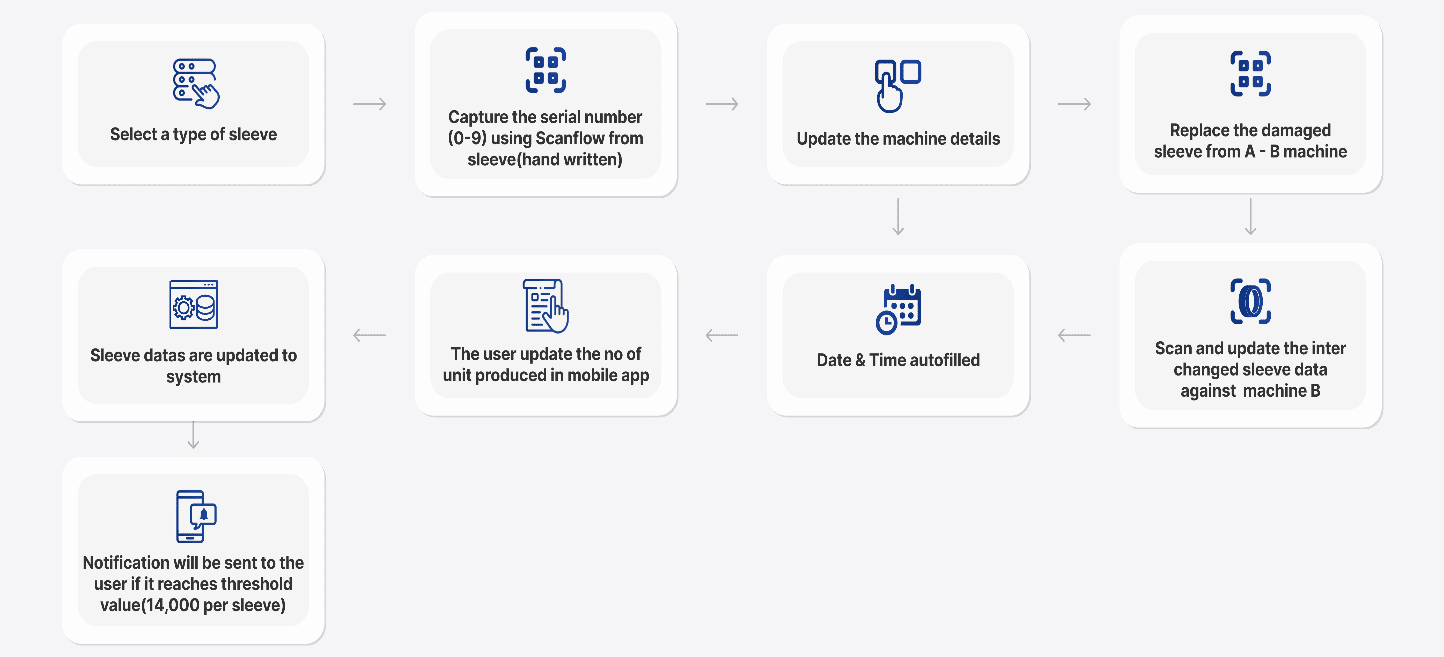

- Automating Workflows for Greater Efficiency

Manual data entry is labor-intensive and prone to mistakes. AI introduces automation across industries, reducing the need for human intervention while improving accuracy and speed. This is particularly valuable in environments requiring high-volume data capture.

Benefits of AI-automated workflows include:

Faster Data Processing: AI captures and processes large volumes of data in seconds, accelerating operations in industries like logistics and automotive.

Error Reduction: AI eliminates human error by accurately reading and recording alphanumeric information, even from difficult angles or damaged surfaces.

Seamless Workflow Automation: AI integrates with existing ERP systems, warehouse management software (WMS), and supply chain platforms to automate data transfer and reporting.

Industries such as manufacturing and retail benefit significantly from automated workflows, as AI can track incoming and outgoing shipments, verify product details, and ensure smooth operational transitions.

- AI for Data capture: From Capture to Insight

AI doesn’t just capture data. Once collected, the data is processed, organized, and integrated with existing systems to provide a comprehensive view of business operations.

Applications of AI for data management across industries include:

Inventory Control: In warehousing and logistics, AI tracks product movement and ensures real-time updates, reducing miscounts and stock discrepancies.

Automated Audits: AI facilitates internal audits by automating the collection and verification of critical data, ensuring compliance with industry regulations.

Data Accuracy and Reporting: AI improves reporting precision by capturing real-time data across multiple touchpoints, enhancing supply chain visibility and operational transparency.

By automating data management, businesses can process vast information efficiently while maintaining accuracy, ultimately enhancing decision-making and optimizing resource allocation.

- Industry-Specific Use Cases of AI in Data Capture

AI’s adaptability makes it invaluable across multiple sectors, where it enhances efficiency and reduces human error. Here’s how AI-driven data capture transforms different industries:

Automotive Industry: AI simplifies VIN plate scanning, improves inventory accuracy, and facilitates compliance tracking across vehicle fleets.

Logistics & Supply Chain: AI automates serial number scanning for package tracking, delivery validation, and warehouse automation, ensuring faster and more accurate logistics.

Manufacturing: AI captures tire sidewall numbers and other industrial identifiers, streamlining product lifecycle management and enhancing production efficiency.

Retail & Consumer Goods: AI supports large-scale inventory tracking and customer data management, improving efficiency in managing supply chains and retail stock.

Healthcare: AI assists in capturing device serial numbers and alphanumeric codes on medical instruments, ensuring accurate records for regulatory compliance.

The Future of AI in Data Capture

The future of AI visual inspection solutions is poised to bring even more advanced capabilities to data capture and management. With ongoing advancements, AI will offer:

Improved Recognition Accuracy: Enhanced models for capturing data from irregular surfaces, low-light environments, and damaged labels.

Integrated Systems: Seamless communication with broader digital ecosystems, including IoT devices and smart supply chains.

Scalable Automation: Greater scalability for industries handling high volumes of alphanumeric data, ensuring accuracy across diverse applications.

Conclusion: AI is Redefining Data Capture

AI is transforming the way industries handle data capture, moving beyond traditional methods to deliver faster, more accurate, and automated solutions. From VIN plate scanning in the automotive sector to serial number scanning in logistics, AI enhances efficiency and reduces human error across various touchpoints.

By integrating AI visual inspection workflows and AI for data capture, businesses can automate complex processes, improve operational accuracy, and gain real-time insights. This shift not only optimizes resource allocation but also ensures smoother, more efficient workflows across industries.

As AI continues to evolve, its applications in data capture will expand, offering smarter, more scalable solutions that drive innovation and operational excellence. Embracing these advanced technologies is no longer optional, it’s essential for businesses looking to stay competitive in a data-driven world.

To stay ahead of this curve, Explore Scanflow AI and see how it can benefit your business operations, visit – https://www.scanflow.ai/get-in-touch/