In automotive manufacturing, precision in tire identification is non-negotiable. But inside warehouses, the way tires are received, stored, and retrieved still relies heavily on manual intervention, leading to mismatches, delays, and an inability to manage inventory effectively. Sidewall data capture introduces a system of record built directly from the tire, enabling smarter, faster, and more accurate warehouse operations.

The Problem with Manual Tire Identification

In most tire warehouses, the process begins with unloading. Tires are manually counted and logged using either handheld scanners or visual checks. From this point forward, tracking relies on printed barcodes, handwritten logs, or product labels that are easy to misread or lose. The warehouse is left operating on estimates, assumptions, and static records.

This causes multiple cascading problems:

- Inaccurate SKU matching: Selecting the wrong tire model or size during retrieval is common when multiple similar variants are stored in close proximity.

- Manual data entry errors: Serial numbers and model information are often typed in by hand, increasing the risk of mismatch or duplication.

- Lack of visibility into tire aging: There is no reliable mechanism to track how long each unit has been stored, leading to slow-moving stock building up unnoticed.

- No real-time inventory insight: Most systems only offer a point-in-time view, which becomes outdated as soon as stock is moved or reallocated.

- Increased turnaround time: The time it takes to find, verify, and dispatch the correct tire grows, especially as SKU complexity increases.

- High man-hour cost: Staff must spend time on low-value tasks like physical checks, double entry, and re-scanning due to initial inaccuracies.

In fast-moving production environments, these issues quickly become bottlenecks – not just for the warehouse, but for the entire supply chain that depends on it.

Why Tire Sidewall Data Capture using AI Changes the Game

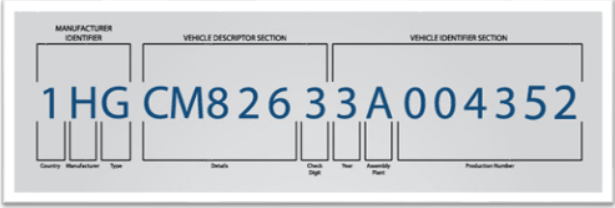

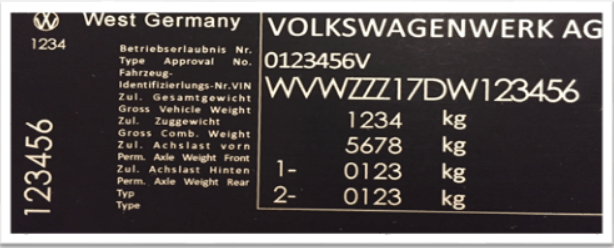

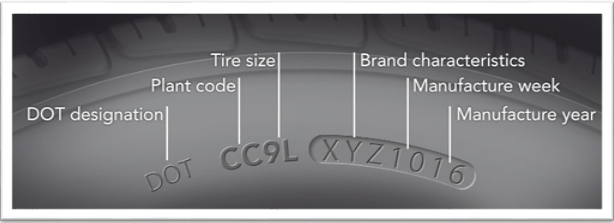

- Every tire has essential data embedded in its sidewall. This includes:

- The Tire Identification Number (TIN)

- Size and load index

- Manufacturer and model

- Batch or production code

Instead of relying on external labels, barcodes, or manual logs, sidewall data capture uses computer vision and optical character recognition to extract this information directly from the tire. The system identifies each unit as it is received, moved, or retrieved without requiring any manual input.

This data is immediately matched to the expected SKU and stored in the warehouse management system in real time. As a result, the warehouse has a live, continuously updated inventory view based on what is actually in storage, not just what was scanned in at the door.

Key Outcomes Enabled by AI Sidewall Capture

1. Asset-Level Identification at Entry

Tires are identified individually as they are unloaded, with precise data linked to each unit. This eliminates reliance on aggregated batch-level logging or barcode stickers that may detach or degrade.

2. Reduced SKU Mismatch During Retrieval

Operators retrieve tires based on validated data from the sidewall, not assumptions or packaging labels. The system flags any discrepancies between what is picked and what is expected.

3. Live Tracking of Tire Aging

Because each tire is scanned and time-stamped at arrival, its storage duration is tracked automatically. This enables FIFO or FEFO practices and prevents the creation of slow-moving or expired stock.

4. Real-Time Warehouse Snapshot

Management gets a complete picture of what is stored where, down to the model and age of each unit. This allows for better layout planning, stock rotation, and dispatch prioritization.

5. Space Utilization Optimization

With clear data on high-movement SKUs, warehouse teams can adjust placement zones and stacking logic to reduce time and effort spent on retrieval.

6. Reduction in Man-Hour Cost

Automated capture eliminates the need for repeated checks, re-scanning, and dual entry. Fewer errors mean fewer corrections, and fewer hands are needed to manage day-to-day tracking tasks.

Moving from Manual to Measurable

The shift from manual identification to structured AI sidewall capture is not just about saving time. It is about enabling tire warehousing operations to work with a level of data integrity and speed that matches the rest of the automotive manufacturing process.

Inaccurate or missing tire data delays dispatches, inflates inventory cost, and slows down assembly. When identification happens at the source; at the moment the tire is unloaded, these problems no longer accumulate. Warehouses become faster. Decisions become more informed. Stock becomes more visible and manageable.

Conclusion

Sidewall data capture transforms warehouse operations from manual and reactive to intelligent and data driven. By building traceability from the physical asset itself, it eliminates errors at the point of entry, improves selection accuracy during retrieval, and gives real-time visibility into every tire in the system.

For tire manufacturers, OEMs, and their warehousing partners, the message is simple: better data starts at the sidewall and the time to capture it is now.

Bring Accuracy & Control Back to Tire Warehousing

If your teams are still spending time on manual tire checks, SKU revalidations, or inventory clean-ups, you’re losing more than just time – you’re losing traceability, efficiency, and cost control.

Scanflow lets you capture tire sidewall data directly from the tire; fast, accurate, and fully integrated into your existing workflows.

No guesswork. No double entry. Just clean data, from source to dispatch.

Book a walkthrough with our team to see how Scanflow fits into your warehousing environment.

Schedule a demo or Download SDK to start.