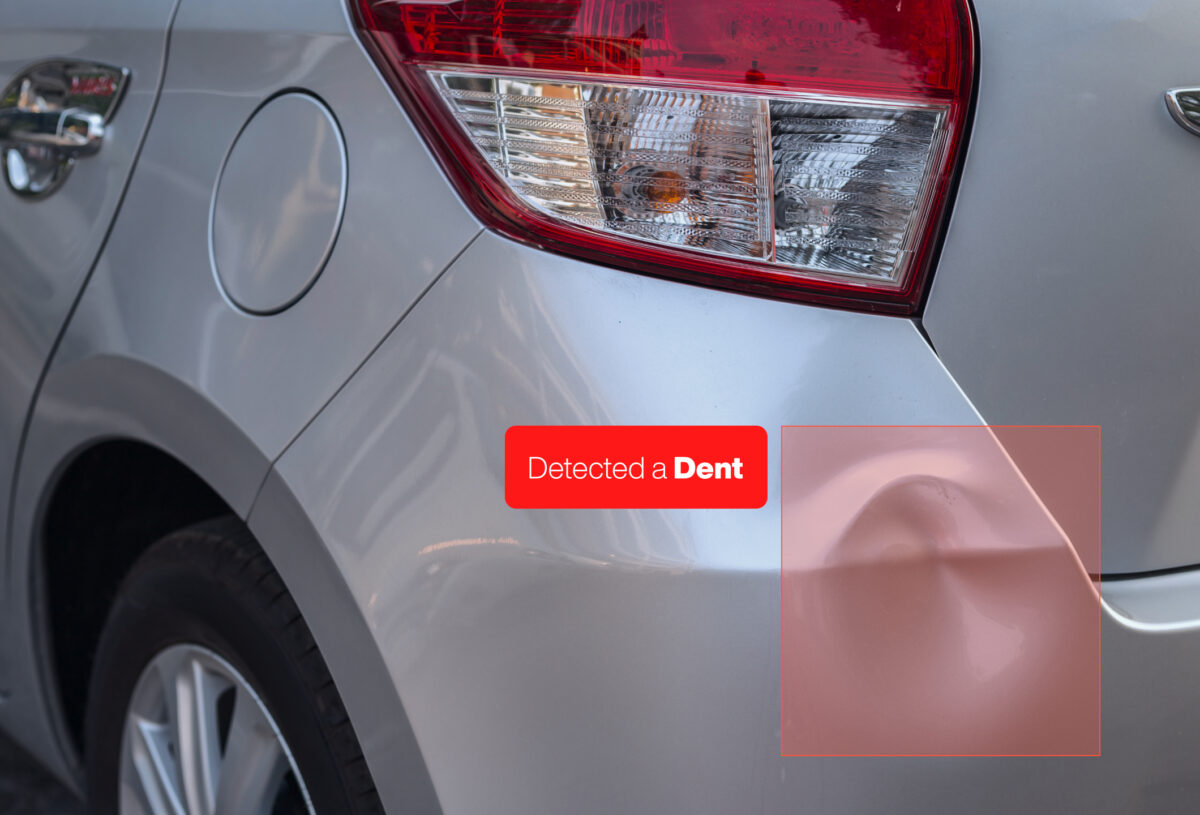

In the dynamic and demanding field of automobile manufacturing, the need to uphold rigorous quality standards is paramount. Automotive components must be flawless to ensure optimal vehicle performance, reliability, and compliance with environmental regulations. Among these, the catalyst component—essential for controlling emissions—demands particularly meticulous inspection. Catalysts must be free from defects that could impact vehicle efficiency, durability, or pollutant emissions. Any defect could have far-reaching consequences, not only for product quality but also for brand reputation and regulatory compliance.

Traditionally, the inspection process for catalysts has been conducted manually, with human operators assessing each component through up to 20 specific checkpoints to ensure it meets quality standards. While effective to a degree, this manual process is inherently flawed. It is slow, labor-intensive, and highly susceptible to human error, resulting in inconsistencies that challenge the manufacturer’s ability to maintain a high-quality standard. As production scales, maintaining both speed and accuracy through a manual process becomes nearly impossible. Additionally, the monotonous nature of repetitive inspection tasks can lead to fatigue and oversight, further increasing the likelihood of defects slipping through.

These challenges reveal the need for a more advanced and efficient approach – one that can handle the high volume of inspections with both speed and precision, eliminate human error, and seamlessly adapt to increasing production demands. The solution would need to ensure the thorough, accurate, and repeatable inspection of catalysts, providing manufacturers with the confidence that each component meets stringent industry standards. Recognizing these requirements, the manufacturer sought a solution that could overcome the limitations of manual inspection and offer a step-change in quality assurance. This created an opportunity for Scanflow to bring its expertise in AI-driven solutions to the forefront.

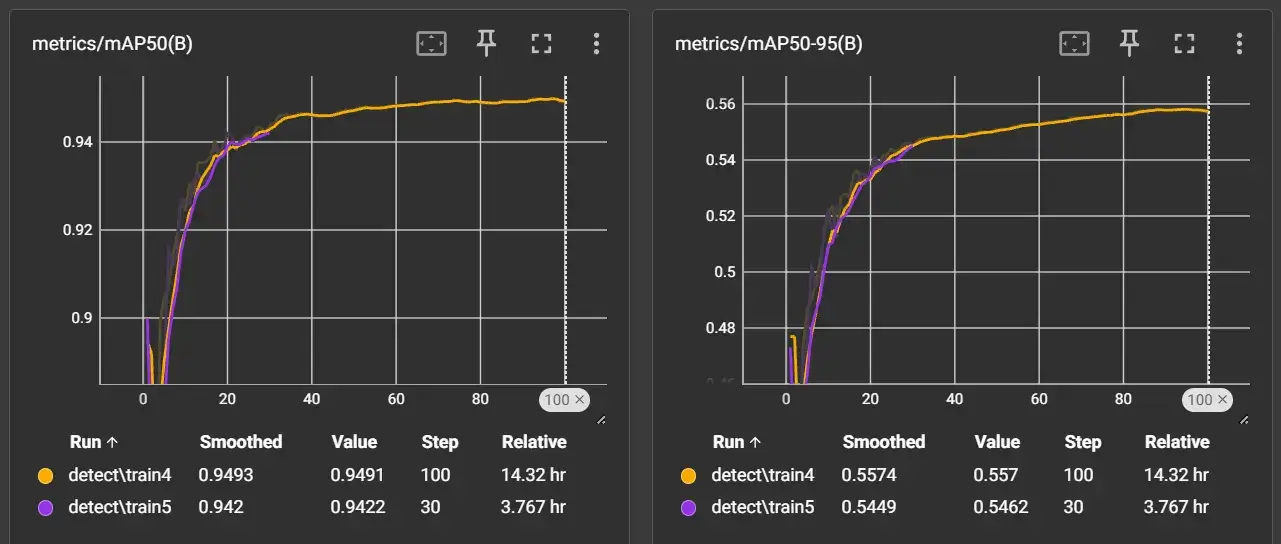

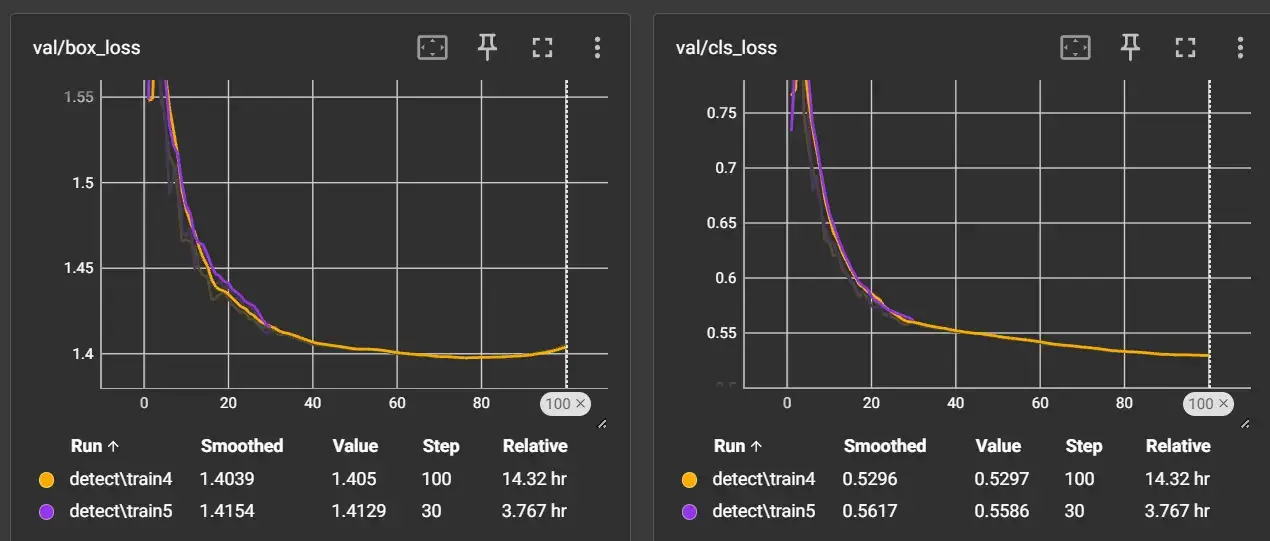

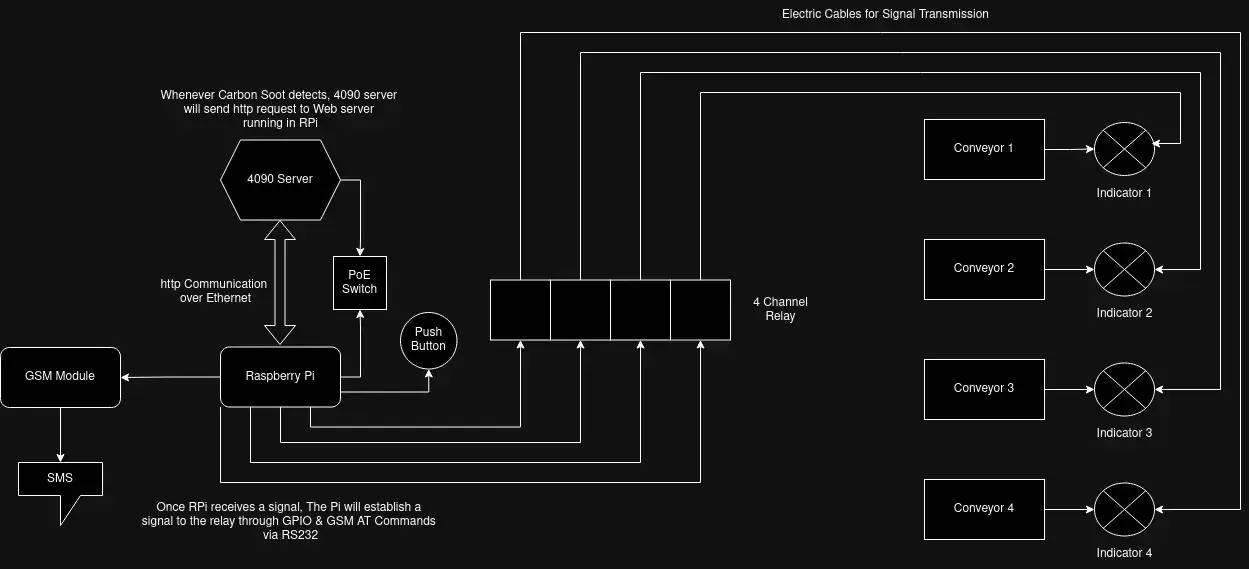

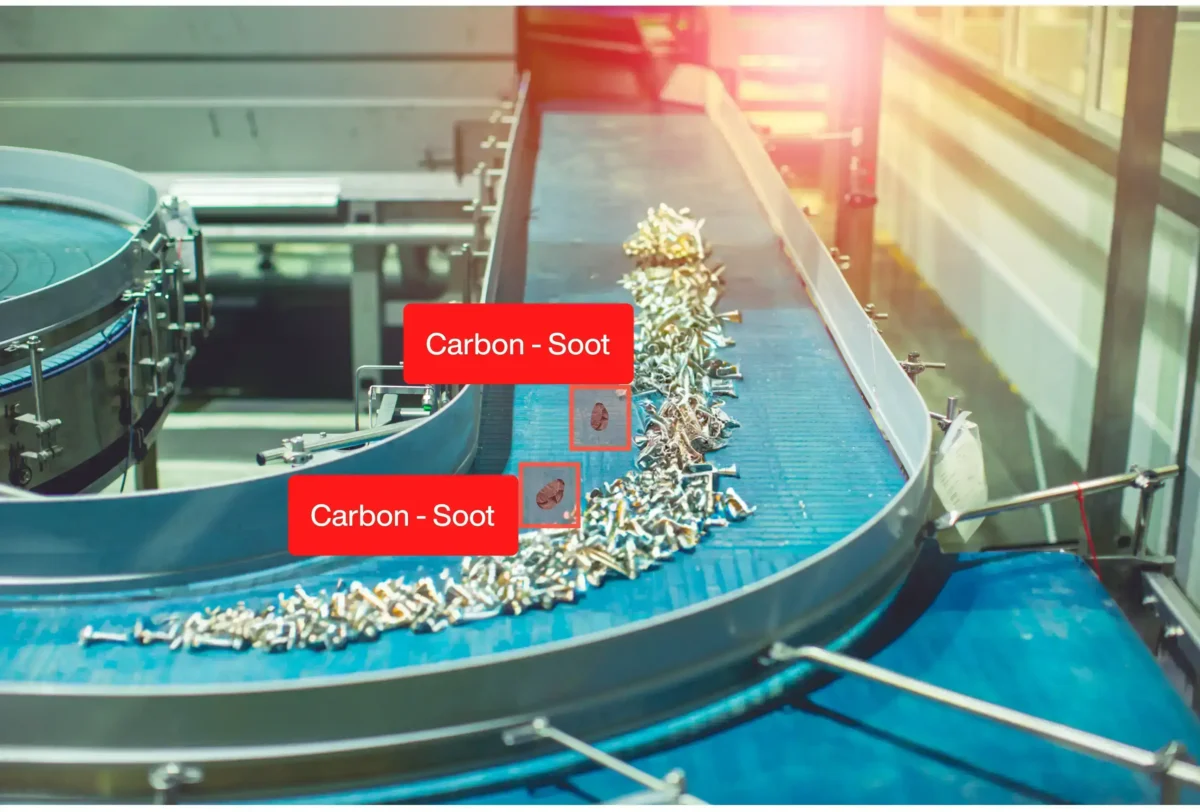

To address the limitations of manual inspection and meet the manufacturer’s high standards, Scanflow introduced an AI-powered computer vision system tailored for catalyst inspection. This cutting-edge solution leverages the latest advancements in computer vision and machine learning to automate the inspection process, offering unparalleled accuracy, speed, and reliability.

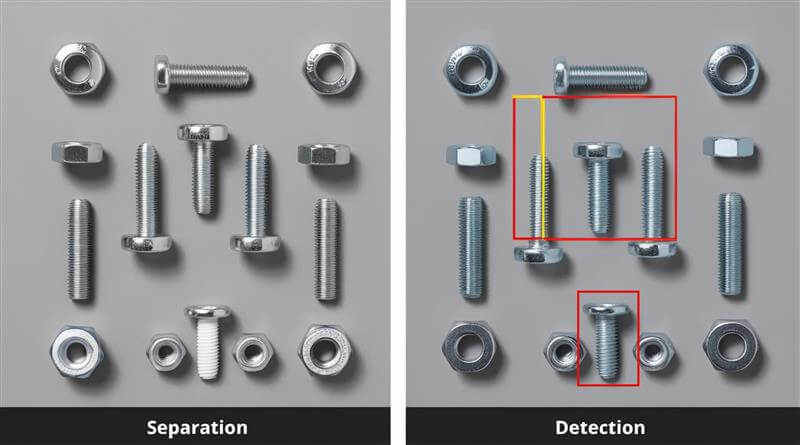

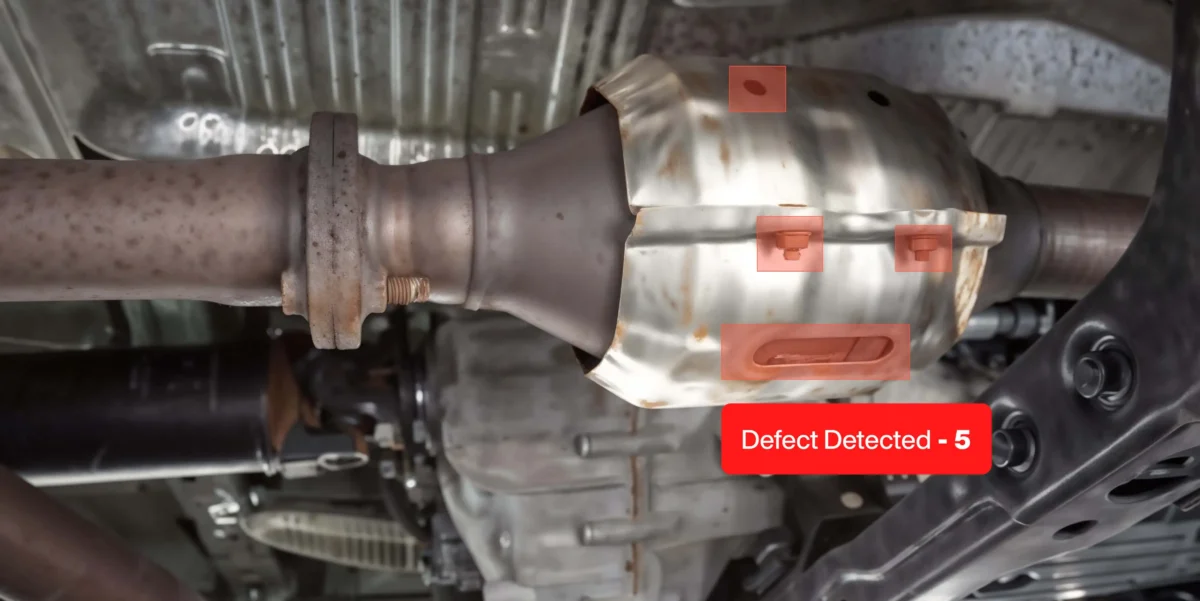

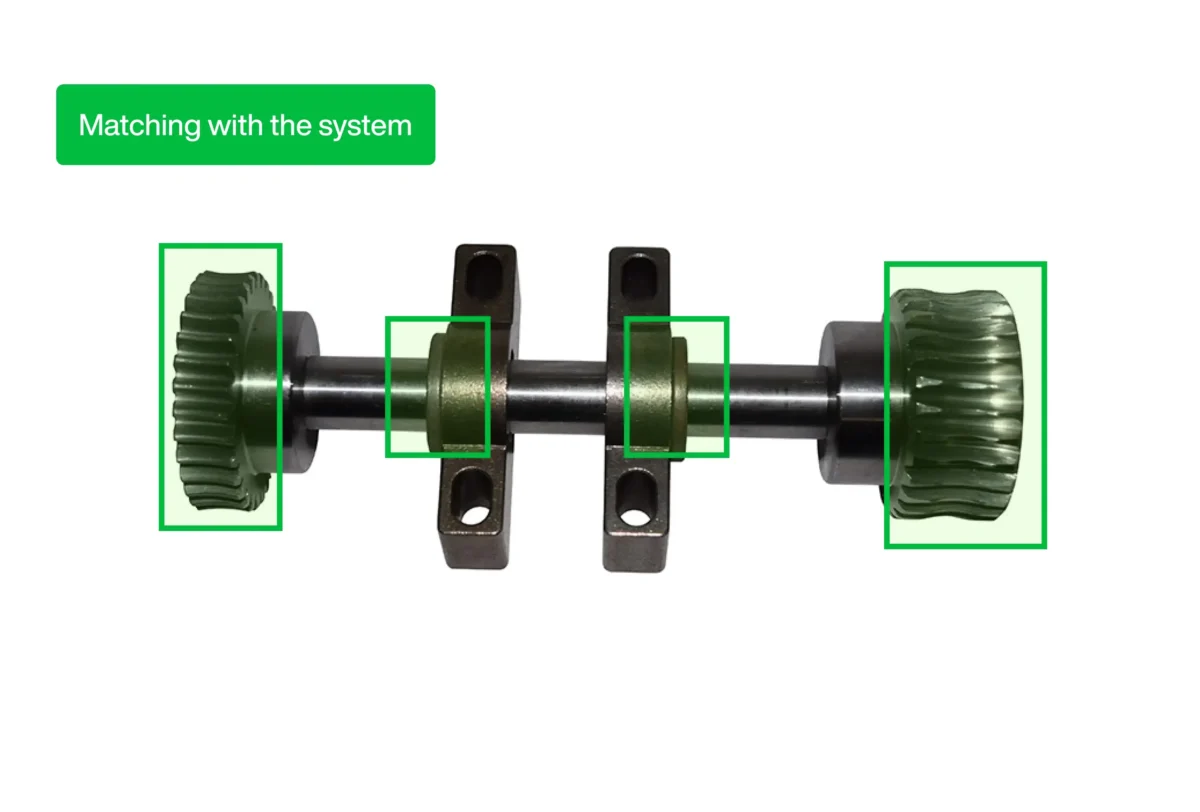

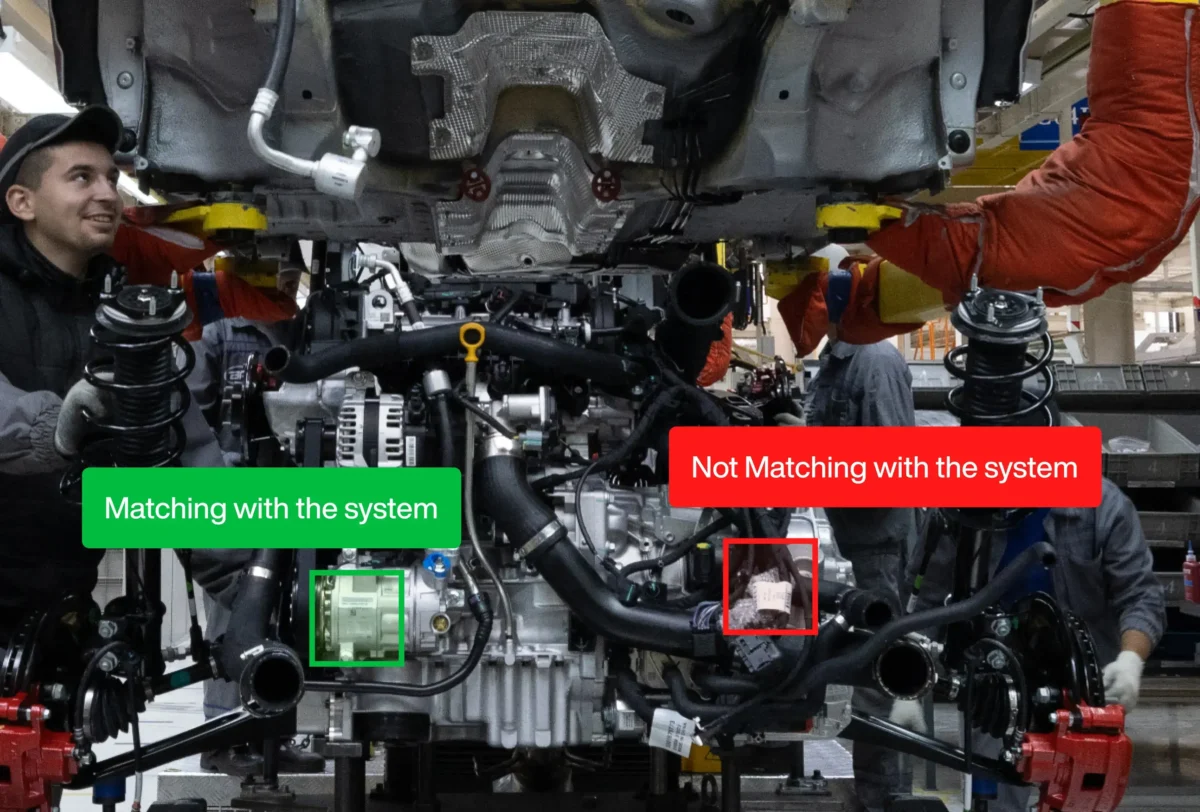

The core of Scanflow’s solution is a sophisticated AI system designed to recognize a range of defects across all 17-20 critical checkpoints on each catalyst component. Using high-resolution imaging and complex machine learning algorithms, the system inspects every component in real time as it moves along the production line. It identifies even the most subtle defects, ensuring that no component with potential issues makes it past inspection. This real-time analysis replaces the need for manual intervention, creating a streamlined process that maintains the highest level of consistency and accuracy.

To ensure seamless integration with the manufacturer’s existing workflows, Scanflow’s AI computer vision system is fully compatible with the current production infrastructure. This compatibility allows the solution to be implemented without major disruptions, enabling the manufacturer to transition smoothly from manual to automated inspection. The system not only performs real-time inspections but also provides advanced reporting capabilities, offering manufacturers full visibility into inspection outcomes. Detailed reports are generated for each inspection cycle, ensuring that manufacturers have a robust record of quality checks for every component produced. These reports also facilitate compliance with regulatory requirements and allow for better traceability of each unit.

Additionally, Scanflow’s AI solution offers predictive insights by analyzing patterns in defect occurrence. By flagging recurring issues, the system enables trend analysis, helping the manufacturer proactively address potential problems in the production process before they escalate. This predictive capability enhances preventive maintenance, reducing the risk of production delays and helping maintain continuous high-quality output.

One of the most compelling advantages of this AI-driven solution is its scalability. As production demands increase or new components are introduced, the system can easily be adapted to accommodate additional checkpoints or even different types of inspections. This scalability positions the manufacturer to evolve with the market, ensuring that quality assurance processes remain agile and future-proof.

The implementation of Scanflow’s AI-powered computer vision system has transformed the catalyst inspection process, delivering measurable improvements in quality, efficiency, and overall operational performance. By automating 100% of the inspections, the manufacturer has eliminated the inherent risks of human error, achieving consistently high inspection accuracy and reliability. This has led to a marked reduction in error rates, minimizing the likelihood of defective catalysts reaching the market. With fewer defects, the manufacturer has experienced a significant decrease in warranty claims and recalls, protecting brand reputation and reducing financial liabilities associated with faulty components.

The speed of inspection has also greatly improved. By performing all inspections in real time, the AI system has accelerated the overall production cycle, enabling the manufacturer to increase output without sacrificing quality. This boost in efficiency has allowed the manufacturer to meet production targets more reliably, even as demand fluctuates, ensuring a more resilient and responsive operation.

Furthermore, the shift to an automated inspection process has reduced the manufacturer’s dependency on manual labor for inspection tasks. With repetitive, detail-oriented inspection work now handled by AI, employees are freed up to focus on higher-value activities that contribute more strategically to the organization’s goals. This reallocation of human resources has not only boosted operational efficiency but has also fostered a more engaging and rewarding work environment for employees.

Scanflow’s solution has also empowered the manufacturer with valuable data and insights. The AI system’s reporting and analytics capabilities enable trend analysis, helping the manufacturer identify patterns and root causes of defects over time. This proactive approach to quality management allows the manufacturer to address issues at their source, improving long-term product quality and consistency. Additionally, by providing detailed inspection records, the system supports regulatory compliance and enhances transparency, which is particularly valuable in the highly regulated automotive industry.

Beyond its immediate impact, this AI-powered inspection system provides a scalable and adaptable solution that can be extended to other components or inspection processes within the manufacturing line. The success of this implementation has set a new standard for quality assurance within the organization, and Scanflow’s solution serves as a model for other applications of AI-driven inspection in the automotive industry. This strategic shift has enabled the manufacturer to not only meet but exceed industry quality standards, positioning them as a leader in innovative quality control practices.

In conclusion, Scanflow’s AI-driven catalyst inspection system has delivered transformative benefits for the manufacturer, from improved accuracy and speed to enhanced data insights and operational flexibility. This success story underscores the power of AI to redefine quality assurance in automotive manufacturing, showcasing how intelligent automation can drive both operational excellence and a competitive edge. By harnessing Scanflow’s innovative technology, the manufacturer has solidified its commitment to quality and efficiency, reinforcing its position at the forefront of industry innovation.