In today’s competitive industrial landscape, streamlining workflow management and optimized workforce productivity play pivotal roles in achieving operational excellence and delivering customer delight. Adopting innovative solutions and leveraging technology are indispensable for maintaining a competitive edge in the landscape of industries.

A UK based retail pharmacy faced significant challenges with tracking inventory, which hindered their ability to maintain real-time inventory control and effectively track medical supplies.

However, their decision to adopt Scanflow into their workflows brought about a transformative success story, revolutionizing their inventory management processes and positively impacting their business performance.

The Challenges:

The pharmacy faced difficulty with various challenges related to inventory management and medical supplies tracking which led to,

Slow inventory process: Slow inventory leads to outdated information, making it difficult to access real-time inventory data, hindering inventory management and potentially impacting decision-making.

Inability to View Inventory: The inability to view and track incoming and outgoing medicine supplies in real-time made it difficult to identify potential stockouts or manage expiration dates effectively.

Inability to do bulk scanning: This leads to delays in restocking, inaccurate stock records, and potential disruptions in patient care.

Time-consuming Inventory Checks: Manual data entry can only be used at specific locations, leading to time-consuming and labor-intensive inventory checks.

Inaccurate Data: The issues with negative stock quantities and discrepancies due to scanning errors leading to discrepancies in inventory records and maintaining stock availability.

Lack of visibility: Difficulty in identifying the individuals who scanned in and out hinders the accurate tracking of inventory movements.

The Scanflow Solution:

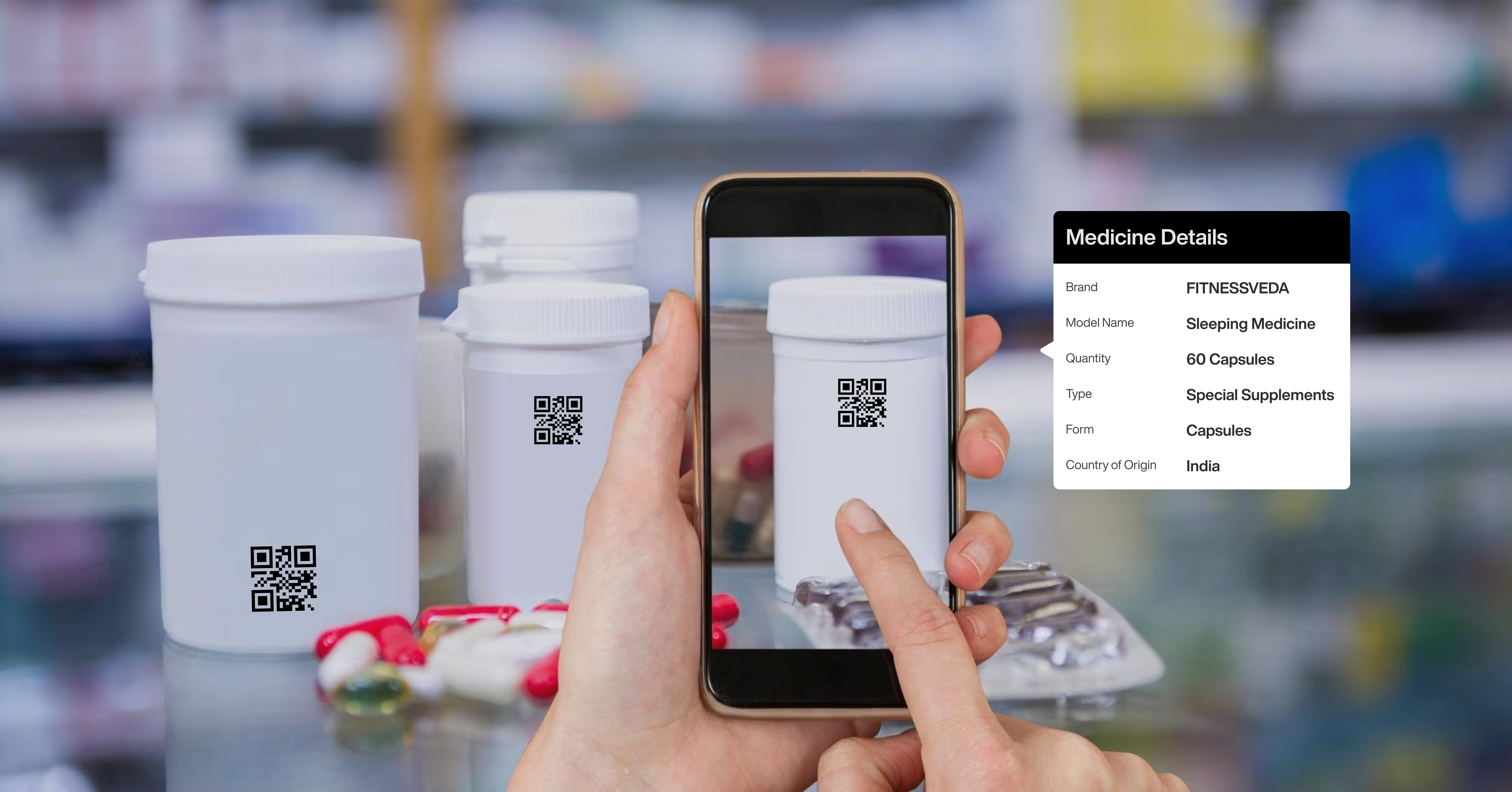

Scanflow solution offers several key features that addressed their pain points and streamlined their inventory management processes. Scanflow helps in real-time tracking of inventory by capturing any type of data, including text, numbers, barcodes, and QR codes.

- Scanflow efficiently captures text, barcodes, and REF codes from incoming and outgoing medical supplies, enabling pharmacists to access critical information like dosage and expiry dates. With document scanning, Scanflow can verify patient prescriptions which can be easily accessed on any smart device, ensuring efficiency in the pharmaceutical workflows.

The stock levels can be accurately monitored in real time and the information is valuable for ensuring stock availability, managing expiration dates, and avoiding stockouts or excess inventory.

Flexibile Integration: Scanflow can be easily integrated with smart devices like smartphones and tablets and backend systems like POS, empowering workers to conduct inventory checks from anywhere within the facility.

Batch scanning with high Accuracy: Scanflow batch scanning helps in quickly tracking and updating inventory by ensuring accurate and up-to-date inventory records.

Real-time Tracking: Scanflow enables real-time tracking of medicine supplies allowing to monitor the movement of supplies from arriving at the warehouse until they reach the shelves.

Analytics and Insights: Scanflow provides valuable insights, helping to optimize inventory levels, identify slow-moving items, and manage expiration dates efficiently.

The Results:

The adoption of Scanflow into their workflow has led to a series of remarkable business outcomes.

Enhanced Efficiency: With the ability to conduct inventory checks using smart devices the workers saved significant time and effort, leading to increased productivity.

Accurate Inventory Records: The reduction in data entry errors ensured that inventory records were precise, reducing the risk of stockouts and excess inventory that contributes to smoother operations and cost-effective purchasing practices.

Improved Stock Availability: Real-time tracking helps to replenish stock promptly, ensuring that essential medicines were always available to meet customer demands.

Reduced Costs: By eliminating the need for any external devices, the pharmacy experienced cost savings, enhancing their overall profitability.

Customization based on Needs: Each pharmacy has its unique requirements and workflows. Scanflow is flexible enough to accommodate specific needs that allows customization to match the existing workflow processes.

Better Customer experience: With a reliable inventory management system Scanflow consistently provided excellent service to their customers, resulting in higher satisfaction rates and increased customer loyalty.

The success story of this pharmacy serves as an inspiring example of how implementing innovative technologies into the workflow process can transform business operations like cost reduction and improved efficiency. By optimizing their operations and providing real-time visibility into their inventory, Scanflow not only improved operational processes but also delivered better customer experiences. This technology adoption demonstrated the power of innovation and technology in shaping the future of business.

Discover how Scanflow can level up your business with smart inventory management solutions at https://www.scanflow.ai/