How Tire Sidewall Scanning using AI is transforming tire warehousing in Automotive Manufacturing

In automotive manufacturing, precision in tire identification is non-negotiable. But inside warehous...

3 Mins read

Posted on Apr 16, 2025

July 27, 2023

3 Mins read

In the ever-evolving world of manufacturing, companies face constant pressure to enhance operational efficiency and reduce downtime to remain competitive. For many industrial businesses, challenges such as inaccurate tracking and unplanned downtime can hinder production processes and escalate operating costs.

A leading tire manufacturing company faced significant pain points that hampered their operational efficiency and led to costly disruptions in their manufacturing process. The company struggled with tracking sleeve lifetimes accurately, resulting in unplanned downtime, increased operating costs, and inefficiencies in maintenance scheduling.

However, all this changed when the company embraced Scanflow’s AI-based automated sleeve monitoring solution with advanced text scanning technology.

The Challenges

The tire manufacturing company had pain points that affected their operational efficiency and led to delays in their manufacturing process, The notable challenges are as follows:

Unplanned Downtime:

The company faced an inability to predict sleeve failures and schedule maintenance in advance. The sleeve breakages during operation caused costly delays and productivity loss which affected overall efficiency.

Manual and Time-consuming Monitoring: The company relied on labor-intensive and time-consuming manual methods for tracking sleeve usage. This was prone to errors and lacked real-time insights into sleeve lifetimes which hindered efficient production planning.

Limited Sleeve Lifetime Monitoring: Difficulty in effectively monitoring sleeve lifetimes in machines. This lack of visibility into remaining useful life hindered timely replacements which resulted in unexpected breakdowns during operations.

Inaccurate Tracking during Sleeve Transfers: The sleeve lifetimes are not accurately tracked when transferred between machines, using worn-out sleeves in different machines caused disruptions and led to untimely breakdowns and production delays.

Inefficient Maintenance Scheduling: The absence of a predictive maintenance system hampered the optimization of maintenance schedules. Some machines received unnecessary maintenance which delayed the risk of breakdowns.

Increased Operating Costs: The unplanned downtime, inefficient maintenance practices, and production delays led to higher operating costs. The lower productivity levels contributed to increased expenses.

The Scanflow Solution

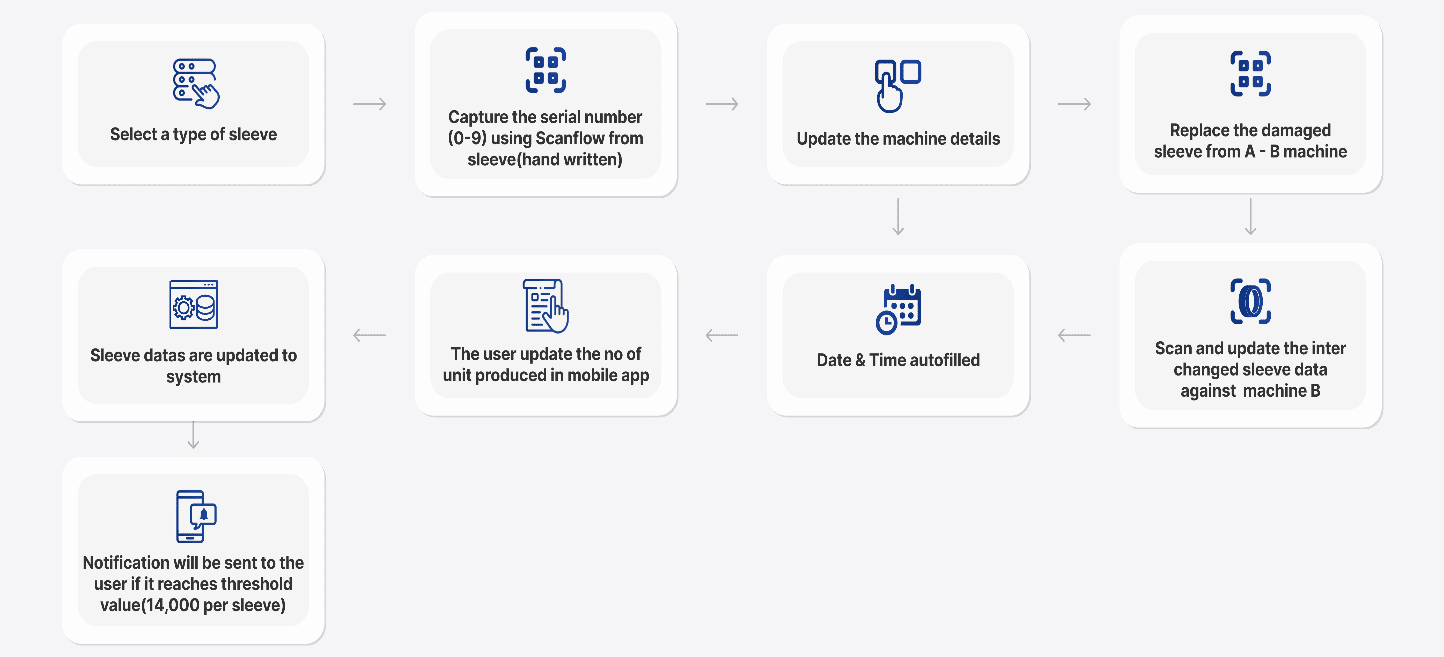

Scanflow addresses these pain points with its Intelligent text scanning which leverages an automated sleeve monitoring solution. This innovative system offered the following solutions:

Scanflow offers real-time insights, predictive maintenance capabilities, and standardized tracking methods by capturing serial numbers, making it a game-changer for optimizing tire manufacturing operations.

Enhanced Sleeve Lifetime Monitoring: Scanflow enabled comprehensive tracking of each sleeve’s lifespan through a centralized database. This real-time tracking empowered operators to plan timely replacements, avoiding unexpected breakdowns.

Accurate Sleeve Tracking during Transfers: By establishing a connection between sleeves’ unique identifiers and machine data, the system ensured accurate tracking during transfers. Operators were notified if a sleeve nearing its end-of-life was about to be moved to another machine.

Predictive Maintenance and Minimized Downtime: Scanflow analyzed sleeve usage patterns, predicting potential failures in advance. The timely notification helps in proactive maintenance, minimizing unplanned downtime and production delays.

Automated and Efficient Monitoring: With automated monitoring, the manual and time-consuming tracking process was eliminated. Real-time insights into sleeve lifetimes improved overall operational efficiency.

Optimized Maintenance Scheduling: The predictive maintenance system allowed them to optimize maintenance schedules, reducing unnecessary servicing and minimizing the risk of breakdowns.

Reduced Operating Costs: By eliminating unplanned downtime and streamlining maintenance practices, the company experienced a significant reduction in operating costs associated with emergency repairs and rush orders.

Standardized Monitoring for Varied Sleeve Types: Scanflow’s advanced text scanning technology enabled standardized monitoring even for sleeves without scannable text identifiers, ensuring a uniform monitoring system.

The Scanflow Workflow with Automated Sleeve Monitoring

The Results

The implementation of Scanflow into their workflow has led to a series of remarkable business outcomes.

Reduced Downtime and Improved Productivity: The automated Sleeve monitoring solution continuously tracks the condition and usage of each sleeve in real-time. This reduced downtime and optimized maintenance schedules lead to improved overall production efficiency.

Reduced Operating Costs: By preventing unplanned breakdowns and emergency repairs, operating costs associated with rush-ordering replacement sleeves are significantly reduced.

Enhanced Quality Control: The system accurately tracks the usage history of each sleeve, allowing for the identification of anomalies or deviations in the manufacturing process. Better quality control ensures consistent and high-quality tire production, meeting industry standards and customer expectations.

Streamlined Operations and User-Friendly Interface: The solution offers a user-friendly mobile app that simplifies data input and provides notifications on maintenance needs. With automated tracking and data entry, the chances of human errors are minimized, enhancing the accuracy of production records.

The implementation of Scanflow’s advanced Intelligent Text scanning for sleeve monitoring solution proved to be a game-changer for the tire manufacturing company. By effectively addressing the pain points, the company experienced improved operational efficiency, reduced downtime, and enhanced cost-effectiveness.

This success story serves as a testament to the transformative power of AI-based solutions in driving excellence in manufacturing Industries.

Discover how Scanflow can transform the operational efficiency of manufacturing process: Text Scanning – Text Scanning Software for Smart Devices – Scanflow | Barcode Scanning Software

How Tire Sidewall Scanning using AI is transforming tire warehousing in Automotive Manufacturing

3 Mins read

Posted on Apr 16, 2025

How AI is Transforming Data Capture Across Industries

4 Mins read

Posted on Mar 17, 2025

This privacy policy sets out how Scanflow uses and protects any information that you give Scanflow when you use this website. Scanflow is committed to ensuring that your privacy is protected. We shall ask you to provide certain information by which you can be identified when using this website, then you can be assured that it will only be used in accordance with this privacy statement.

Scanflow may change this policy from time to time by updating this page. You should check this page from time to time to ensure that you are happy with any changes.

What We Collect

We may collect the following information:

Name and job title

Contact information including email address

Demographic information such as postcode, preferences and interests

Other information relevant to customer surveys and/or offers

What we do with the information we gather

We require this information to understand your needs and provide you with a better service, and in particular for the following reasons:

Internal record keeping.

We may use the information to improve our products and services.

We may periodically send promotional emails about new products, special offers or other information which we think you may find interesting using the email address which you have provided.

From time to time, we may also use your information to contact you for market research purposes. We may contact you by email, phone, fax or mail.

We may use the information to customize the website according to your interests.

Security

We are committed to ensuring that your information is secure. In order to prevent unauthorized access or disclosure, we have put in place suitable physical, electronic and managerial procedures to safeguard and secure the information we collect online.

How we use cookies

A cookie is a small file which asks permission to be placed on your computer’s hard drive. Once you agree, the file is added and the cookie helps analyze web traffic or lets you know when you visit a particular site. Cookies allow web applications to respond to you as an individual. The web application can tailor its operations to your needs, likes and dislikes by gathering and remembering information about your preferences.

We use traffic log cookies to identify which pages are being used. This helps us analyze data about webpage traffic and improve our website in order to tailor it to customer needs. We only use this information for statistical analysis purposes and then the data is removed from the system.

Overall, cookies help us provide you with a better website, by enabling us to monitor which pages you find useful and which you do not. A cookie in no way gives us access to your computer or any information about you, other than the data you choose to share with us.

You can choose to accept or decline cookies. Most web browsers automatically accept cookies, but you can usually modify your browser setting to decline cookies if you prefer. This may prevent you from taking full advantage of the website.

Links to other websites

Our website may contain links to other websites of interest. However, once you have used these links to leave our site, you should note that we do not have any control over that other website. Therefore, we cannot be responsible for the protection and privacy of any information which you provide whilst visiting such sites and such sites are not governed by this privacy statement. You should exercise caution and look at the privacy statement applicable to the website in question.

Controlling your personal information

You may choose to restrict the collection or use of your personal information in the following ways:

Whenever you are asked to fill in a form on the website, look for the box that you can click to indicate that you do not want the information to be used by anybody for direct marketing purposes

If you have previously agreed to us using your personal information for direct marketing purposes, you may change your mind at any time by writing to or emailing us at info@scanflow.ai We will not sell, distribute or lease your personal information to third parties unless we have your permission or are required by law to do so. We may use your personal information to send you promotional information about third parties which we think you may find interesting if you tell us that you wish this to happen. If you believe that any information, we are holding out from you is incorrect or incomplete, please write to or email us as soon as possible at the above address. We will promptly correct any information found to be incorrect.