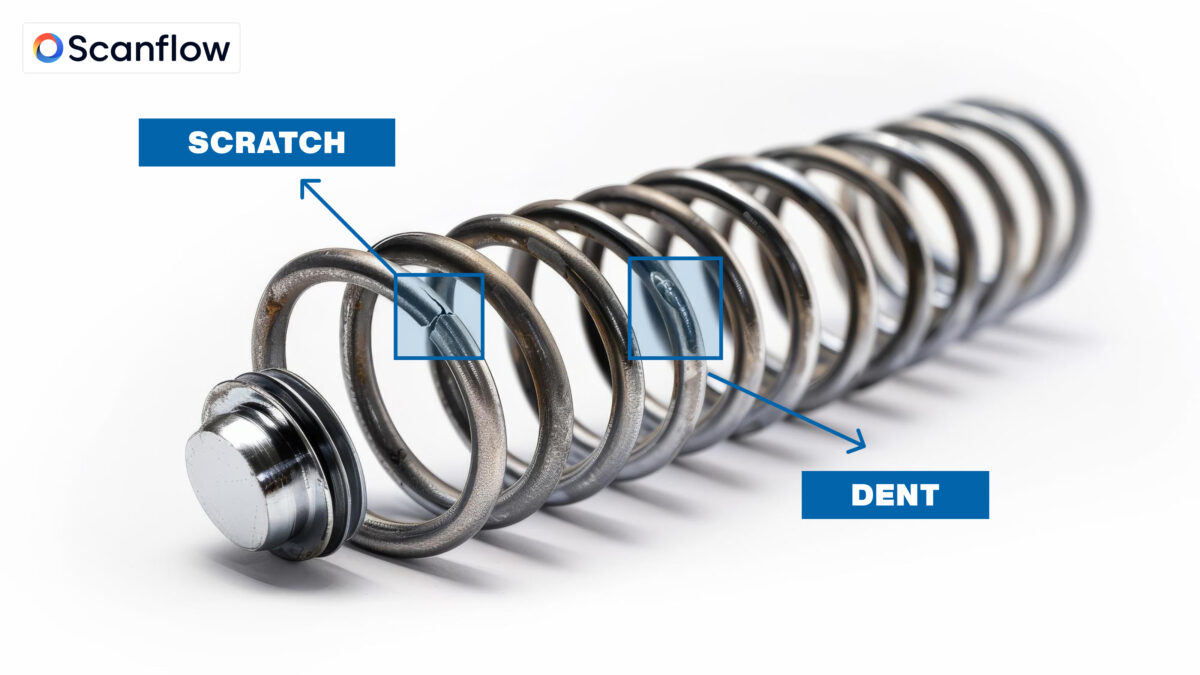

Coil springs are vital components in automotive and industrial machinery, ensuring stability and smooth operation. However, their constant exposure to stress, environmental factors, and wear can lead to cracks, holes, and dents that compromise performance and safety. Early detection is crucial, and with AI based technology, the process has become more efficient and reliable than ever.

Why Coil Spring Damage is a Critical Concern?

Even minor defects in coil springs can lead to serious issues such as:

1. Reduced Performance: Faulty springs affect load handling and vehicle stability.

2. Increased Risk of Failure: Cracks and holes can worsen over time, leading to sudden breakage.

3. Costly Repairs: Neglecting small defects often results in expensive replacements or system-wide damage.

Manual inspections, while necessary, are prone to human error and may fail to detect subtle signs of damage.

Revolutionizing Detection with AI Automation

AI-driven coil spring damage detection has transformed how damage is identified, making inspections faster, more accurate, and cost-effective. Here’s how this technology works:

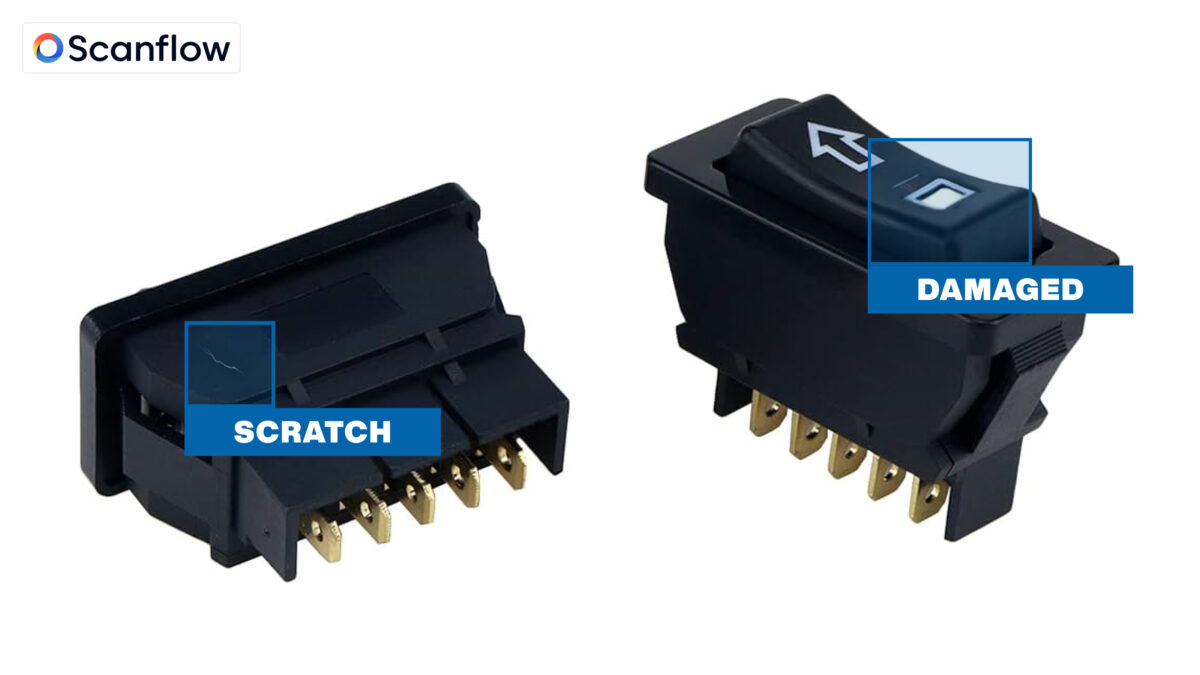

1. High-Precision Imaging: AI captures detailed scans of coil springs, identifying even microscopic defects like hairline cracks or surface irregularities.

2. Automated Analysis: The system analyses patterns and compares them to benchmarks, flagging deviations that indicate potential damage.

3. Comprehensive Reporting: Real-time insights and reports help technicians take immediate action, preventing further deterioration.

4. Seamless Integration: The AI system integrates effortlessly into existing quality control workflows, reducing downtime and operational disruption.

Key Benefits of AI-Driven Detection

By automating the detection process, businesses can:

1) Ensure Safety: Proactively address damage to maintain operational safety and stability.

2) Reduce Costs: Early identification minimizes repair expenses and prevents extensive damage.

3) Save Time: Automated analysis speeds up inspections, freeing up resources for other tasks.

4) Enhance Accuracy: Eliminate human error for more reliable results.

Why Scanflow is the Ideal Solution?

Scanflow leads the charge in AI enhanced coil spring detection. Its advanced imaging and AI capabilities are specifically designed to detect cracks, holes, and dents with unparalleled accuracy. Businesses across industries trust Scanflow for its:

a) Precision and reliability.

b) Easy integration into existing systems.

c) Real-time reporting for actionable insights.

Conclusion: Embrace the Future of Coil Spring Inspection

AI-driven technology is reshaping the way coil spring damage is identified, ensuring safety, efficiency, and cost savings. With solutions like Scanflow, businesses can stay ahead of potential issues and maintain the highest standards of quality and performance.

Take the first step towards automated coil spring inspections.

Contact us today to learn how Scanflow can revolutionize your detection process!

3 Mins read