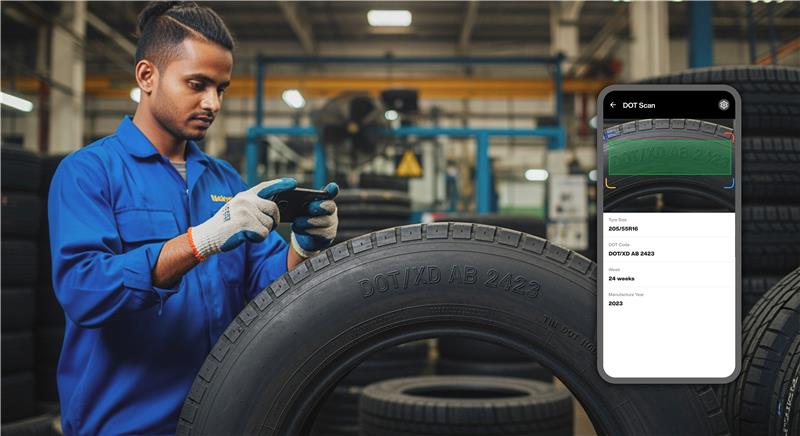

Scanflow’s tire sidewall scanning system harnesses mobile edge offline SDK that supports for both Android, iOS, Web and API which accurately and efficiently extract critical information such as DOT, size, model number, and brand from real-time images using smartphones and tablets. This article presents a technically robust account of each pipeline stage, relevant algorithms, and formulaic logic.

System Architecture: Edge-Driven Pipeline

Device & Data Capture Layer

Operators use a mobile app integrated with the Scanflow SDK. Images of the tire sidewall are captured using the built-in camera, under varying environmental conditions (light, dust, wear).

Real-time pre-processing ensures noise reduction and optimal imaging

Iproc = Enhance (Iraw), where Iraw is the input image and Iproc is the denoised, contrast-adjusted output.

Pre-processing workflow for tyre sidewall capture using the Scanflow Core SDK on mobile devices which has Scanflow Customized AI Camera. This step is critical, only high-quality frames make it to later stages, so scanning accuracy starts here.

The app uses Scanflow’s SDK (ScanFlowCameraSession, ScanTrustCameraManager)

-

- Requests camera permissions and ensures device orientation (typically portrait).

- SDK manages autofocus, torch (flash), and zoom, adapting dynamically (for low-light correction, centering prompts, etc.).

Frame Filtering Algorithms:

Every frame is rapidly checked with a sequence of filters:

Sharpness Detection

Uses algorithms like Laplacian variance: computes edge sharpness. If variance is below a threshold, frame is too blurry and discarded.

S=Var(∇2I)

Where S is sharpnes, I frame image.

Motion Blur/Artifact Check

Simple frame-to-frame comparison assesses motion using optical flow or frame difference. If the tyre area shifts too much between frames, it’s rejected.

Exposure and White Balance:

Frames under- or over-exposed (too dark/bright) are detected with pixel intensity statistics:

Only frames passing ALL filters are sent to model inference (segmentation/OCR).

for (Frame frame : cameraBuffer) {

if (!isSharp(frame)) continue;

if (isMotionBlurred(frame)) continue;

if (!hasGoodContrast(frame)) continue;

if (!isProperlyExposed(frame)) continue;

if (!isCentered(frame)) continue;

processFrame(frame); // Pass to segmentation & OCR

}Image Segmentation & Region of Interest (ROI) Detection

The SDK’s CV engine applies edge detection and region heuristics (Canny, Hough, and deep learning models) to localize key regions:

ROI = (Iproc) ROI = Detect (Iproc)

Segmentation leverages Custome model architectures for instance localization.

Optical Character Recognition (OCR)

-

- The cropped sidewall region is processed by a custom OCR model (typically CRNN or CRAFT), tuned on embossed/engraved, low-contrast, and worn characters.

- Each character in the region outputs a probability vector:

P(ci) = Softmax(zi)

-

-

- The recognized string S is constructed: S=Concat(argmax(P(ci))

-

- DOT, TIN, size, and serial/model numbers are extracted using regular expressions and neural attention layers:

DOT = RegexSearch( S, DOT pattern )

Size= RegexSearch( S, Size pattern )

Manufacturer/brand is classified via context signals and dictionary lookups.

Semantic Parsing & Data Structuring

Extracted entities are tagged and validated:

Week/year codes from DOT (e.g., 4-digit decode: YYWW)

Size pattern (Width/Aspect Ratio R Diameter), matched by regex or neural text extraction

Model number filtered by fuzzy match to database records

The feature vector:

Vtire = [DOT, Size, Model_No, Brand]

Local Edge Validation & Timestamping

All critical data is validated on-device using checksum algorithms and cross-checks with reference datasets:

Valid = fcheck( Vtire, DBtire )

Timestamp and geotag are appended for traceability.

Edge Custome Model: Tuning for Tire Sidewall Capture

Model Training & Optimization

Training images are annotated for texture, contrast anomalies, and typical defect cases. Trained with 1 Million data sets

Loss functions combine categorical cross-entropy (for OCR) and segmentation IOU

Ltotal=αLocr+βLiou

Dataset diversity (thousands of brands, types, conditions) ensures generalizability and noise resilience.

The Mobile models are quantized using for real-time, low-latency inference (<300ms typical).

The mobile will completely run on edge with Offline capability for field/yard use.

Data Usage in Model Training

The foundation of Scanflow’s tire sidewall scanning model lies in meticulously collected, annotated, and curated datasets, incorporating diverse real-world edge cases. The dataset is used for training various AI models that perform segmentation, text detection, and recognition in a multi-stage pipeline:

- Input Data: Raw images and video frames captured from mobile cameras under differing lighting, angles, and tire wear conditions.

- Annotations: Detailed bounding boxes, segmentation masks, and character-level labels enable supervised learning.

- Augmentation: On-the-fly data augmentations such as rotation, scaling, illumination changes, blurring, and noise simulate real-world scanning variations.

- Validation Sets: Separate from training, used continuously across epochs for hyperparameter tuning and generalization checks.

Multi-stage Training

- Stage 1: Backbone Feature Extraction

- Model: Stabilize and standardized based model architectures.

- Purpose: Learn low-level and high-level image features common to tire sidewalls.

- Stage 2: Segmentation Training

- Loss Functions:

- Classification loss (Lcls) using cross-entropy.

- Bounding box loss (Lbox) via Smooth L1 or IoU.

- Mask loss (Lmask) using binary cross-entropy for pixel-wise predictions.

- Loss Functions:

L=Lcls+Lbox+Lmask

Data Privacy and Security For Enterprise System Integration

- Scanflow SDK primarily performs on-device processing, ensuring raw images and processed data never need to leave the mobile device.

- Data export is user-controlled, encrypted, often only metadata or interpreted text is sent to cloud or backend systems.

- Secure key management for SDK licenses maintains system integrity.

- Local Processing: Scanflow performs all essential OCR and image processing on the mobile device (edge), eliminating the need to send raw images or sensitive data over the network initially.

- Volatile Memory Storage: Images and intermediate data are kept only in volatile memory buffers during scanning sessions.

- Immediate Data Purge: Raw capture frames and temporary data buffers are wiped securely immediately after recognition.

Comparison statistics report of Scanflow and other Commercial SDKs available in Market.

Here is a comparative chart that illustrates the stability, accuracy, and performance (speed) of the Scanflow SDK versus three other commercial tire sidewall scanning SDKs. The values are on a 0-100 scale based on typical reported benchmarks and user feedback:

- Scanflow leads across all three parameters with high stability (92), accuracy (95), and performance (90).

- Competitor A follows with decent but lower metrics.

- Competitors B and C lag further behind, especially in accuracy and performance.

This visual comparison helps users quickly comprehend how Scanflow excels in delivering reliable, accurate, and fast tire sidewall scanning.

- Stability indicates how consistently the SDK performs across different tire types, environmental conditions, and mobile devices.

- Accuracy measures the precision of extracted data like DOT codes, size, model numbers.

- Performance refers to inference speed and responsiveness on edge devices (mobile phones).

Users can visualize Scanflow outperforming competitors on all three parameters, indicating reliability and speed combined with superior detection accuracy.

Such a chart helps technical users quickly assess and compare SDK capabilities for integration or evaluation purposes. If needed, this can be presented as a grouped bar chart with distinct colors per metric for clarity.

Let’s take a comparison metrics with leading Competitor A SDK.

| Metric / Condition | Scanflow | Competitor A | Scanflow Advantage |

|---|---|---|---|

| Overall Accuracy | 96.6% | 85.1% | ✅ +11.5% higher accuracy |

| Old & Glared Tyres | 100% | Not specified | ✅ Proven capability on aged/glared surfaces |

| Blurred Images | 86% | 54% | ✅ Handles blurred captures (partial recovery possible) |

| Accuracy in Challenging Conditions | Very High | Low | ✅ Robust in difficult lighting/angles |

| Consistency Across Conditions | Very High | Moderate | ✅ Reliable across varying scenarios |

Scanflow Leading Metrics (Compared to Competitor A)

| Criteria | Scanflow | Competitor A | Scanflow Advantage |

|---|---|---|---|

| Tyre Compatibility | Works on any tyres | Car tyres only | ✅ Universal tyre support |

| Blurry Image Handling | Excellent | Poor | ✅ Handles low-quality images effectively |

| Challenging Conditions | Handles well | Struggles | ✅ Robust under real-world conditions |

| Offline Support | ✅ Fully Offline | ❌ Requires Internet | ✅ Works without connectivity |

| DOT Code ROI Handling | More flexible | Very narrow ROI box | ✅ Adapts better to varying code areas |

| Partial Value Return | ✅ Returns partial values | ❌ Not supported | ✅ Can decode incomplete DOT codes |

| Text Angle Handling | Tolerates a range of angles | Best when perpendicular | ✅ Works across multiple orientations |

| Default Camera Mode | Uses wide-angle (may need tuning) | Neutral | ✅ Broader field |

Summary

Scanflow’s tire sidewall scanning SDK combines cutting-edge AI models, mobile-optimized processing, comprehensive and accurate data extraction, and seamless integration, backed by industry-leading stability and performance. These technical strengths ensure developers and businesses gain a robust, future proof solution, minimizing operational friction while maximizing insight and efficiency making Scanflow an unmatched choice in the tire scanning ecosystem.

Scanflow delivers enterprise-grade reliability, accuracy, and resilience, positioning itself as the most advanced and deployable tire sidewall scanning SDK in today’s market.