Industries require scanning solutions for workflow operations, driving visibility into resources and distribution activities. Technological innovations have created a great impact on businesses irrespective of industries. This has enhanced the business activities of small to large enterprises bringing differences in operating costs, and employee productivity. Industries like logistics, retail, and manufacturing have eased their workflow by implementing automation thus reducing manual intervention.

Smart devices are paving the way for AI’s transformation of how organizations run. The addition of AI-enabled software to smart devices such as smartphones, and wearables improves performance and perhaps has the potential to replace the need for an external device.

Software scanners are easy to adopt and use which makes them an inevitable solution to any enterprise problem associated with scanners

-

- Quicker data capture with high-precision results

- Increases revenue while cutting down on errors.

- Cost-effective prevents loss of funds due to human error.

- High performance when compared to hardware scanners

- Reduces time in analyzing the quality of the assets, inventory, and products.

- User-friendly integration in any type of smart devices

- List of software scanners that help in Industrial Automation

Scandit is a technological platform for augmented reality (AR) and mobile computer vision solutions for businesses. The company’s software enables unmatched barcode scanning, text and object recognition, and real-time display for any app on any camera-equipped smart device, including smartphones, wearables, drones, and robots. Scandit is integrated into a number of partner systems, including SAP Fiori, Oracle XStore, Epic Rover, etc., and supports a wide range of hardware and software platforms.

The notable clients of Scandit include 7-Eleven, Alaska Airlines, Carrefour, Hermes, Levi Strauss & Co., Mount Sinai Hospital, Sephora, Toyota, Johns Hopkins Hospital, and La Poste.

FOUNDED: 2009

EMPLOYEES: 251–500

LOCATION: Zurich, Switzerland

FUNDING: $273.1M

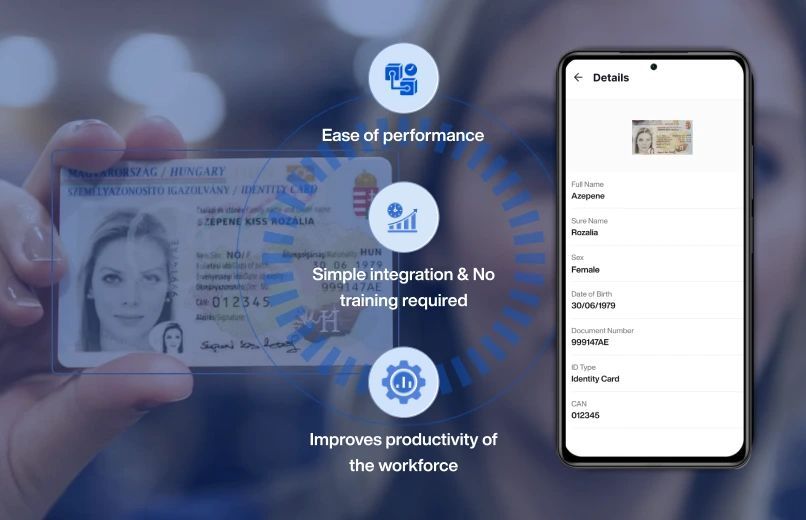

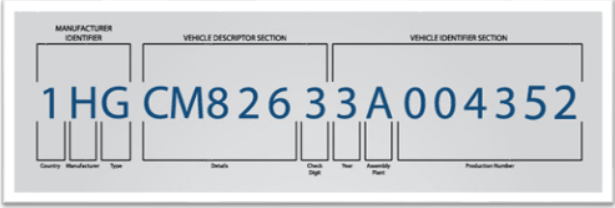

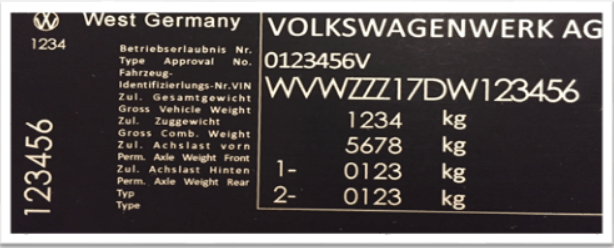

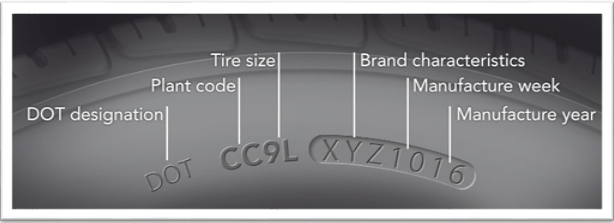

Anyline scanning SDK is used to create real-time mobile OCR apps with the highest recognition rates without the need for server infrastructure. Anyline offers a hassle-free scanning solution that will save time and money. The following industries have benefited from Anyline’s assistance in the digitization process: Utility, Government, MRO, transportation, automotive, tourism, and other product industries.

Anyline’s broad range of dependable technology can handle the most challenging business problems by combining advanced machine learning models with conditioning from the real world.

FOUNDED: 2013

EMPLOYEES: 51–100

LOCATION: Vienna, Austria

FUNDING: $37M

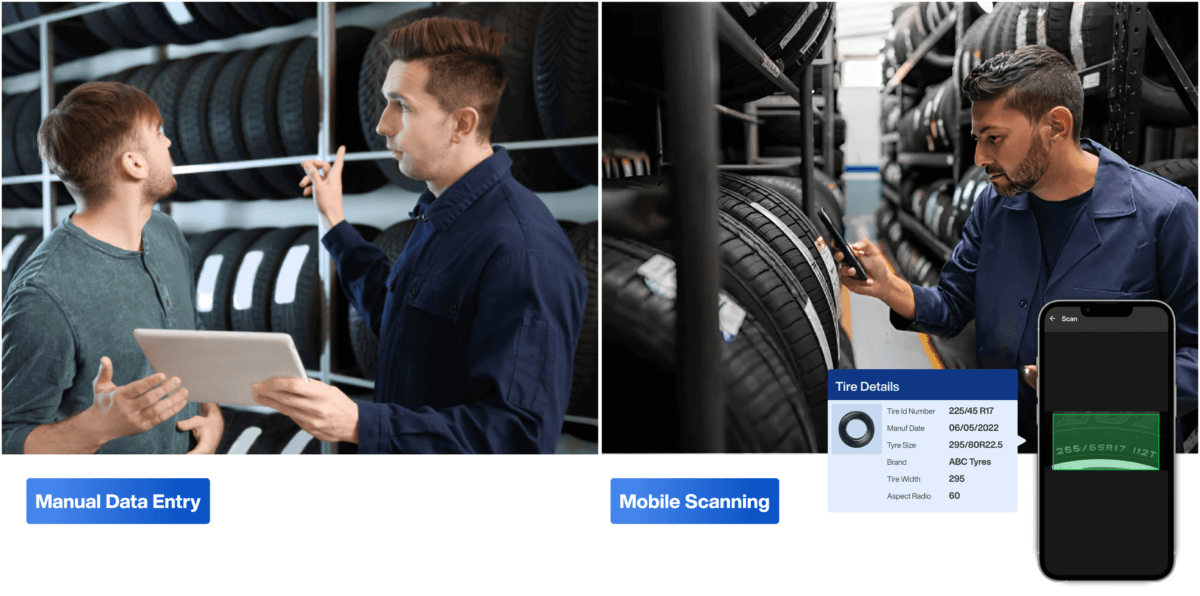

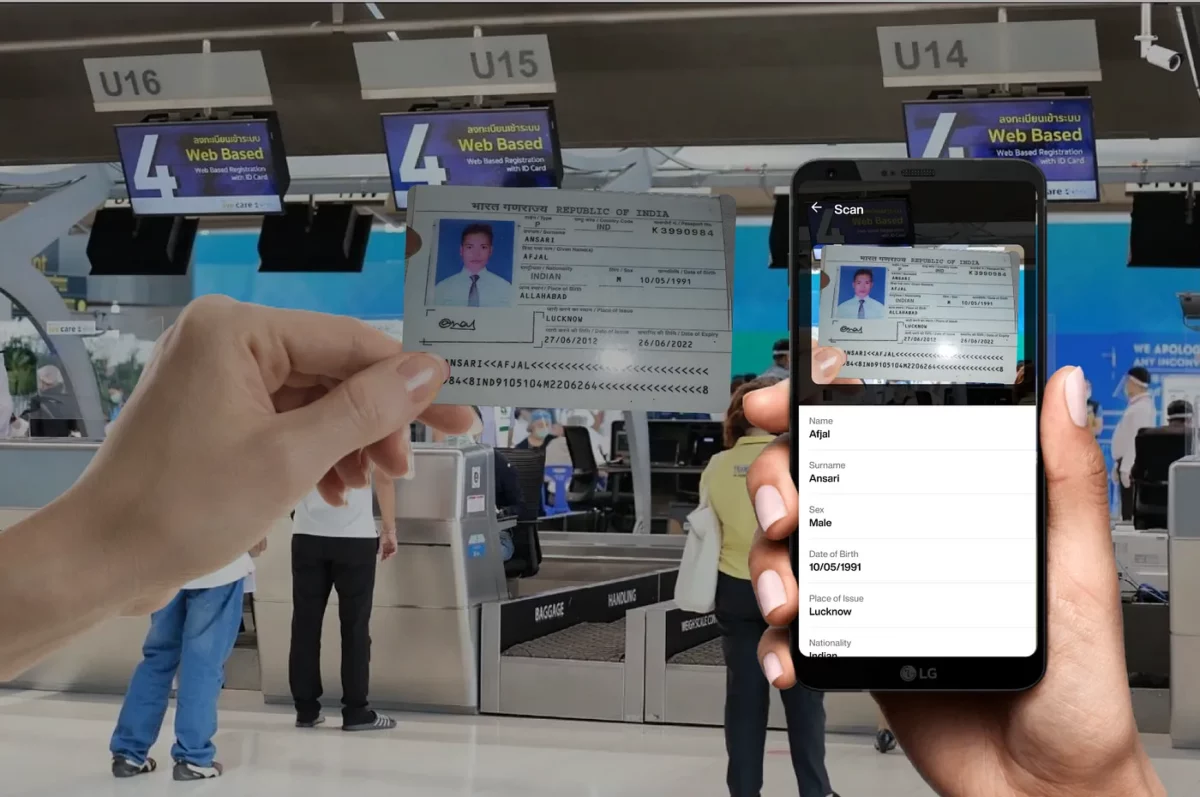

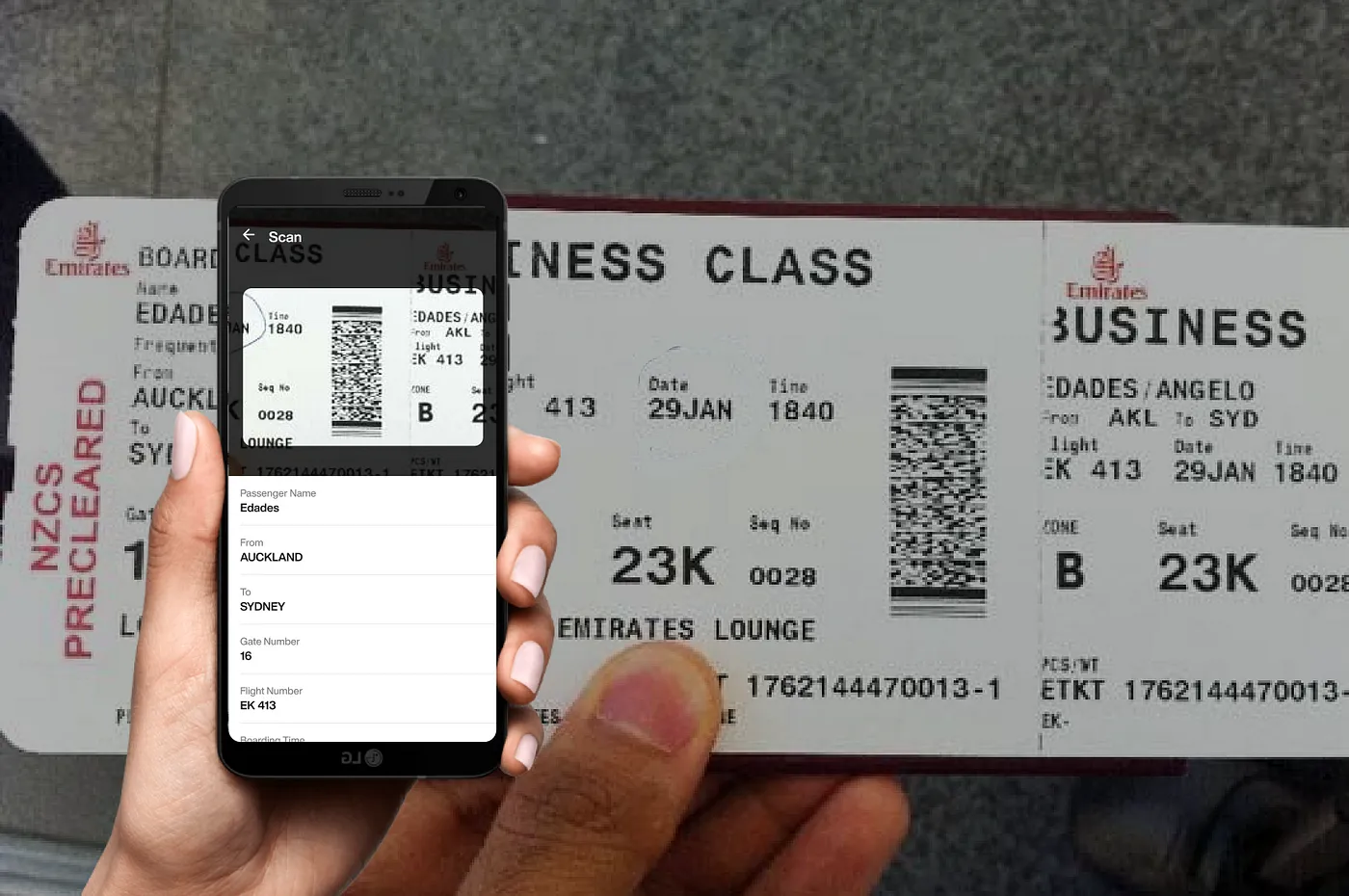

Scanflow is an AI scanner for smart devices that captures data and automate workflows. It can capture any type of data, including text, IDs, numbers, barcodes, and QR codes. Scanflow can be easily integrated with any smart device like smartphones, drones, and other wearable devices. Built with AI-powered solutions, Scanflow can scan in difficult conditions such as low-light low-light environments, long-range distances, and at any angle orientation with high precision and speed.

Scanflow enables users to experience personalized shopping, self-checkout, inventory management, and asset tracking for retail, logistics, and manufacturing industries. Scanflow-powered solutions reduce operational costs and time while boosting worker and customer satisfaction. The goal of Scanflow is to offer enterprise-grade intelligent data capture technologies that help automate workflow processes

FOUNDED: 2021

EMPLOYEES: 11–50

LOCATION: Coimbatore, India

Dynamsoft is a multinational software development company that provides SDK for document capture and barcode applications for various usage scenarios. These SDKs help developers meet document imaging, scanning, and barcode reader requirements when developing web, desktop, or mobile-based applications.

The key areas of Dynamsoft’s research and development are document imaging and barcode decoding. The SDKs are used by developers to remove the need for them to develop their own code. This removes months of work for them by cutting the need to code as well as understand relevant industry standards and requirements. Over the last 18 years, many companies across the world have used Dynamsoft’s SDK in their daily workflows to improve efficiency and reduce cost.

FOUNDED: 2003

EMPLOYEES: 51–100

LOCATION: Vancouver, Canada

-

Scanbot helps businesses all over the world in reducing the expense of human data entry. Scanbot SDK can record analog data from any mobile device. Scanbot is a mobile scanner app for documents and QR codes. Users can create premium quality PDF scans and send them through email or automatically upload them to the cloud such as Google Drive, Box, Dropbox, Evernote, and other cloud services.

Scanbot makes it possible to include scanning and data extraction features into current mobile applications for the banking, insurance, healthcare, and logistics sectors. Any enterprise application can incorporate scanning features and data extraction using SDK’s highly advanced algorithms and machine learning.

FOUNDED: 2011

EMPLOYEES: 11–50

LOCATION: Bonn, Germany

AI-based software scanners can be used by any industry to improve workflow processes and solve business-related issues. Software scanners are an essential part of asset tracking and inventory management and are being incorporated into everyday smart devices to increase data accuracy, eliminate human error, and improve business operations.