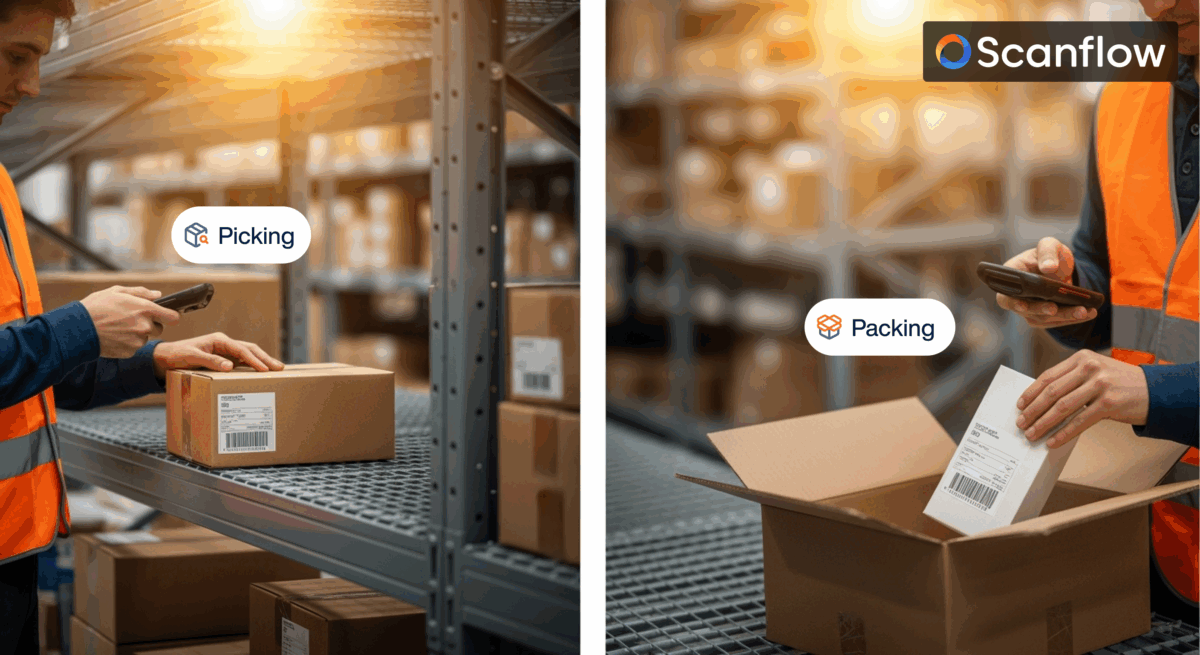

In today’s high velocity supply chain, warehouse operations face pressure to meet rising order volumes, shorten delivery times, and eliminate errors all while maintaining cost-efficiency. Yet, many organizations still rely on manual or semi-automated pick and pack processes that can’t keep pace with operational demands.

Scanflow’s Pick and Pack Automation addresses these inefficiencies through a smart, AI system that brings accuracy, speed, and system-level integration into warehouse workflows. Below, we explore five common challenges warehouses face and how Scanflow solves them.

Challenge 1: Picking Errors and Mislabeling

The Challenge: Manual picking is one of the most error-prone processes in a warehouse. Misselected items, wrong quantities, and labeling mistakes lead to customer dissatisfaction, product returns, and additional handling costs.

How Scanflow Solves It: Scanflow uses AI-driven computer vision to validate every item as it’s picked. The system checks against order data in real-time, ensuring the right SKU and quantity are selected. It also automates label generation and placement, reducing human error and guaranteeing that every item is packed and tagged correctly before dispatch.

Challenge 2: Slow Fulfilment and Dispatch Delays

The Challenge: As order volumes grow, manual processes can’t scale fast enough. Fulfilment teams struggle to meet tight timelines, and dispatch delays become inevitable especially during peak periods.

How Scanflow Solves It: Scanflow speeds up the entire pick and pack cycle by providing guided workflows, real-time verifications, and automated decision points. Operators are directed through optimized picking paths, and AI instantly verifies items before packing. This ensures orders move faster through the warehouse without sacrificing accuracy, helping businesses consistently meet SLA deadlines.

Challenge 3: Lack of Workflow Synchronization Across Warehouse Systems

The Challenge: Many warehouse operations suffer from disconnected systems where picking, inventory, packing, and order management tools function in isolation. The lack of end-to-end visibility causes delays, miscommunication, and inefficient workflows.

How Scanflow Solves It:

Scanflow is built for seamless integration with existing WMS, ERP, and inventory platforms. Its API-first architecture enables real-time data exchange across warehouse functions, aligning the picking, verification, and packing steps into a single, unified process. This synchronization improves coordination, reduces manual intervention, and ensures every action is tracked and recorded across systems.

Challenge 4: Inefficient Packing and Material Waste

The Challenge:

Packing inefficiencies such as selecting the wrong carton size, packing items in the wrong sequence, or using excess filler lead to material waste, damaged products, and higher shipping costs.

How Scanflow Solves It:

Scanflow optimizes packing operations by using AI-assisted logic that selects the ideal packaging based on item dimensions and order requirements. Operators receive packing guidance on-screen, and the system verifies contents before sealing. This minimizes packaging waste, reduces damage risk, and ensures every box is prepared for safe, efficient shipping.

Challenge 5: Lack of Real-Time Visibility and Tracking

The Challenge: Manual processes offer limited insights into order status, picking accuracy, and workforce productivity. Managers are left guessing when problems occur and discovering issues only after a shipment fails or a customer complains.

How Scanflow Solves It: With Scanflow, every step from pick to pack is digitally tracked and logged. Managers get real-time dashboards and visual audit trails, allowing them to monitor orders, identify bottlenecks, and resolve issues proactively. Integration with WMS and ERP systems ensures consistent data visibility across platforms, enabling better decision-making and operational control.

Conclusion

Manual pick and pack operations are no longer sustainable in today’s fulfillment environment. Errors, delays, siloed systems, and lack of visibility not only slow down operations but also increase costs and customer dissatisfaction.

Scanflow’s Pick and Pack Automation offers a comprehensive, integrated solution that eliminates inefficiencies and builds resilience into warehouse operations. With vision-based verification, AI-guided workflows, and seamless system integration, it helps enterprises unlock higher speed, accuracy, and scalability exactly what modern supply chains demand.